Biomass boilers — An expert guide to this renewable energy option

Biomass boilers are a popular source of renewable energy but may not be suitable for every home. Find out what types there are and if one could be right for you

Biomass boilers may not work for every home, but in the right setting can be a great option if you are looking for a reliable, renewable and sustainable heating option. I know because I heated my home with one.

But, if you're not familiar with the technology and are wondering exactly how they work, we've prepared this expert and first hand guide to biomass boilers to help you decide if it's the right choice to power your own home's heating system.

Choosing biomass essentially comes down to location, available space, price and if you have easy access to fuel, but as each type of boiler has different attributes, here's what you need to know.

What do biomass boilers burn?

"Strictly speaking, if you ask what is biomass fuel, the answer is it's anything that's been grown and burns," says Gordon Traill, founder and director of Treco. "Technically it includes things like straw and perhaps recycled materials. However, in relation to what most people consider as biomass, there’s a choice of wood pellets, logs and wood chips."

This is primarily down to the fact that these types of wood based products offer a cleaner burn. Biomass is also considered a carbon-neutral fuel, as CO2 is absorbed by trees as they grow (photosynthesis). And even though CO2 is emitted when the fuel is burned, the amount produced is measured as equal to that absorbed during growth, along with any additional carbon produced while manufacturing and transporting the fuel.

Gordon Traill is founder of Treco, one of the UK’s largest biomass heating suppliers. Founded in 2005, the company has grown into a leading supplier in the biomass heating sector, helping over 1,000 businesses transition from fossil fuels to biomass heating, reducing carbon emissions by 40,000 tonnes annually—the equivalent of nearly 9,000 cars. Gordon is proud of Treco’s customer-centric approach, always ensuring that any system recommended is one he would personally invest in

Types of biomass boiler

When it comes to the different types available to you, biomass boilers are identified by the type of fuel that they use – wood chip, logs or wood pellets. But, what's common to them all is that they burn the fuel to heat hot water, which in turn supplies your heating and domestic hot water system.

However, understanding which type of biomass boiler suits your property best involves taking a more in-depth look at how each type works in order to understand the pros and cons of biomass boilers.

The best starting place is perhaps understanding how much fuel is needed to heat the average home each year – something that is less easy to visualise if you have previously used fossil fuels such as gas, oil or LPG.

Once you appreciate the quantity of fuel required, then you can begin to understand why the type of biomass boiler you choose matters so much.

Log fed biomass boilers

"If we talk about a typical house, the government says the average household uses 25,000 kilowatt hours per year," says Gordon Traill. "So if we take that example of 25,000 kilowatt hours for heating and hot water in relation to a log boiler, it equates to around seven tons of logs a year."

Log boilers are gasifying batch boilers. They operate at much higher temperatures, gasifying the logs, increasing efficiency to over 90%. The boiler will have a log burning chamber that requires logs of equal lengths and thickness to be loaded in and then the door is closed for the duration of the burn.

Ideally a single "burn" or batch of logs is sufficient to heat the home and the hot water storage cylinder for at least a 24 hour period in the winter months.

"However, when you look at the overall usage per year and consider that the seven tons has to be fed, by hand, into a relatively small burning chamber, that’s a lot of fills each year," adds Gordon, noting how in winter it could be up to three times a day in the coldest weather. For some homeowners, this simply isn't an option.

Wood pellet biomass boilers

Wood pellets are considered the most consistent biomass fuel in that they are usually even in size and density. Typically made from forestry waste or by-products, the standard type in the UK is 6mm pellets, made from softwood with a low moisture content.

The benefit of a wood pellet boiler over a log fed one is that they have a box or store next to them known as a hopper. The size of the hopper depends on the output of the boiler, but every hopper has an auger (a bit like a corkscrew) that delivers the pellets to the burner chamber. The benefit of a larger hopper is that your wood pellets can be blown into it from a delivery truck - rather than you needing them to load them by hand from bags.

Alternatively, pellets are available bagged, typically in 10kg or 15kg bags delivered by the pallet load. "I’d alway suggest you opt for as large a pellet store as you can," says Gordon, "as you’ll be able to get a better deal in terms of fuel. As soon as you start having bag deliveries, unless it's a very small property, then there’s a lot of work and they're much more expensive."

It's something I can confirm first-hand, as although I had a commercially-sized biomass boiler, it still burnt wood pellets, so we included a five ton hopper as part of the installation. This meant a delivery truck could arrive, connect to the hopper and blow pellets directly inside.

On those rare occasions when blown-in pellets weren't delivered (read 6 things I wish I'd known before I installed biomass to find out why this can happen), having to handball them in every few days was not feasible as a long-term solution and always worked out to be more expensive.

Wood chip biomass boilers

Wood chips are often made from a variety of different timber products including logs, roots, twigs, bark and leaves, and in a similar way to wood pellet biomass boilers, wood chip versions have a bulk fuel store which means fuel can be loaded in larger quantities, rather than by hand.

If you are producing your own wood chip on site, this can be done using plant machinery. Blown-in deliveries are also available, but will cost a little more.

"Wood chip boilers are the cheapest form of biomass heating," says Gordon Traill, "and it’s what I use myself. However, they are more suited to much larger properties or small-holdings. I've got a farm," explains Gordon, "so I essentially have a mini scheme which covers both commercial and domestic use.

"In addition, wood chip comes in at a lower cost than any of the alternatives per kilowatt hour. In terms of sustainability they’re really good as well," he adds, "because the fuel often doesn't have to travel as far, especially if it's sourced on site.

"But, for a small home, they're not always very appropriate," says Gordon. "On a larger scale or at a commercial level however, then they can be a great option."

Where to locate a biomass boiler

Biomass boilers generally aren't installed inside your home, so it's important to understand how much space you need and where it should be located. Unlike combi boilers for example, which are often located in utility rooms, your biomass boiler won't be as close to hand so you can't keep a regular eye on it in the same way.

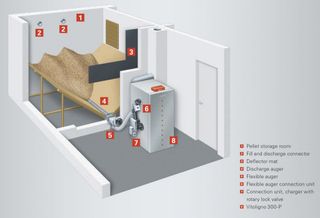

It's common for biomass boilers to be located in a dedicated plant room – although this doesn't have to be a purpose built room. "You need a space about the size of a single garage to house the boilers and fuel store," says Gordon, although how close that space is to your house, isn't as important when it comes to performance.

"As long your pipes are well insulated, the impact of the distance from the house to the boiler is negligible. The losses are so small, it doesn't need to be right next to it." You will of course however need to make sure that it has sufficient ventilation and is considered appropriate by your chosen biomass supplier and installer.

In terms of where I located my biomass boiler, I was fortunate to have an unused garage within a few metres from the proposed end of a new extension. However, the plant room with the heating manifolds for the hot water, radiators and underfloor heating that the hot water had to reach was another 20 metres away. Nonetheless, this never appeared to affect its efficiency in any way.

While the some boilers may only be the size of a four-drawer filing cabinet, it is mainly the fuel storage that requires more space and needs to be accessible, as you'll either be loading by hand or ensuring a delivery driver with a bulk fuel order can get within 20m of your hopper.

How a biomass boiler transfers heat

"Biomass boilers are installed with what's known as a thermal store," explains Gordon. "This stores the heat that burning the fuel creates, the principle being that even if the fuel has run out, the thermal store acts like a battery. It stores the energy and your heating could be running for many hours after the boiler has completely gone out.

"The bigger the thermal store, the longer it will run," says Gordon. "It's exactly the same as the principle with solar batteries. However, it simply stores energy, which means you've got to keep putting it back in. Once the thermal store has run out, so will your heating and hot water."

Speaking from experience, this is another reason why it's important to understand how they work when working out your energy needs to choose the right renewable energy. On those occasions when the boiler had stopped working, the size of my thermal store meant it could continue supplying heat for at least 24-36 hours before we realised. But, when it stopped, this meant taking a trip to the garage, resolving the problem and then waiting for enough fuel to burn to heat the system back up.

It's not as simple as simply re-igniting your gas boiler, so regular checks are recommended - even if your heating is working well.

Assessing whether a biomass boiler is right for you

The size and thermal efficiency of your home has an impact

In big, hard-to-heat properties, the general view is that biomass offers a good option, but less so in more typical new builds or conversions. Likewise in larger new builds biomass can be and is a viable option, particularly if you are looking to be less fossil fuel reliant.

"For me, biomass really starts to work with larger, more difficult to heat properties," says Gordon Traill. "Listed buildings for example," says Gordon, "are a great example of when they can be beneficial – providing plenty of high temperature heat but at a lower running cost."

Cost will be a deciding factor

The main reason they may not be so suitable for smaller properties usually comes down to biomass boiler costs.

The cost of biomass boilers varies far more than oil or gas boilers. The cost will also vary with the type of boiler, the level of automation and sophistication, as well as with size and quality.

"I think that realistically, with the boiler, fuel store and all the relevant install, work and connections to the home, you’re looking at upwards of £25,000," says Gordon. "Some companies may offer it for less, but it will also depend on the size of the system.

"There are some boilers which are very small scale, but there aren't so many of them around, even though they're very good. And, if it was a very small property, then they would be powered with bags of pellets, a less convenient option for some.

"When you get to much larger biomass boilers, many of the people that either run log boilers or chip boilers are self supplying," says Gordon. "So they have some woodland, they live in the country, and they have the availability to get the timber which means the running costs are significantly lower. For a large scale system, this could be as low as 4.5 pence per kilowatt hour," he confirms.

"Unfortunately, biomass boilers get little government support," explains Gordon, "so while you can get £5,000 for a biomass boiler under the Boiler Upgrade Scheme, they are still expensive. It’s just an inescapable fact," he says.

Biomass boiler efficiency vs other fuels

As the efficiency of any heating system will play a part in assessing if biomass is right for you, it is broadly similar to oil or gas, achieving around 80 to 90% efficiency. However, it's the running costs which show a marked difference, compared to air source heat pumps for example, says Gordon.

"It's a little more complicated than saying their efficiency rate isn't great compared to air source heat pumps which claim to operate at a 300% CoP efficiency rate," notes Gordon. "The reality is, this is a moving seasonal number and won’t always equate to that level.

"Electricity which heat pumps need is around 30 pence a kilowatt hour. So, if you get three to one, then you're still paying 10 pence a kilowatt hour for heat. If you if you're getting less than three to one it could be 12 to 14 pence, which is expensive.

"Wood pellets cost around £350 a ton and will deliver around 5000 kilowatt hours per ton which means you're getting around 7.5 pence a kilowatt hour more of delivery," explains Gordon.

"However, if you were to buy logs, they’re actually significantly more expensive than anything else," says Gordon, "which is why most people we would recommend a log boiler to have their own supplies of timber.

"If you were to base your fuel costs on the price of beautiful pallets of kiln logs, they would probably come in around 20 pence a kilowatt hour, which is why they are more suited to homes with woodland."

Making a choice

While deciding if a biomass boiler is right for you involves looking at your existing home or potential build, if you have decided on installing one, there are some key questions to consider when it comes to making the right choice. These involve looking at not just the boiler itself, but also the supplier and installer.

Consider the repuation of the manufacturer, how long they have been in operation and their compliance with the Microgeneration Certification Scheme (MCS). The installer must also be HETAS registered, just as a gas boiler installer needs to be Gas Safe registered and an oil boiler installer needs to be OFTEC registered.

"One thing worth mentioning when it comes to making your final choice," says Gordon, "is that you should always try to buy from a manufacturer that has support in the UK. Check that they work with a supplier where there are trained technicians who can provide spares if things do need repairing.

"It can also help when it comes to annual servicing and maintenance," he adds, "as you won’t be able to find people who can help in the same way you can for fossil fuel boilers." Approved service engineers also have to be on the MCS list.

With regards to the boiler, once you've decided on fuel type, also think about the control system – does the control system address the whole house or individual zones? Does it have remote monitoring and can it be controlled from a PC or App?

Ask about the burner control as the quality of the burner determines the efficiency of the boiler. Good boilers automatically control the air flow over the burner, ensuring it always operates at optimum efficiency and allowing the heat output to match the demand (called modulation).

Also make sure it comes with at least a two year warranty (parts and labour).

FAQs

What size biomass boiler do I need?

"Generally speaking, properties have an Energy Performance Certificate (EPC) and as a rule of thumb, this is your starting point for working out the size of boiler you need," says Gordon Traill. "If you divided your annual consumption by 1500 you'd end up very close to the boiler size.

"So, for example, if you took 25,000 kilowatt hours, divided by 1500, theoretically, you'd need a 16 to 17 kilowatt boiler. In reality, they don't make 17 kilowatt boilers, so it would be 20 to 25 kilowatt.

"EPCs are very helpful from our point of view. People are always look at the energy ratings, but the interesting information for us is the is the kilowatt hours for heating and hot water," says Gordon. "Beyond that, we would calculate all of the things that anybody would do if they were sizing an oil or gas boiler."

How long will a biomass boiler last?

"A good quality one will stand the test of time," says Gordon. "It's almost indefinite, because of the level and weight of construction involved. They are designed to last, particularly those who come from Austrian and German manufacturers."

Does a biomass boiler need much maintenance?

Maintenance will vary with the level of sophistication and is an issue that needs to be directed to the supplier and clearly understood for any particular machine.

In broad terms, boilers will need an annual maintenance service, but, otherwise, the main maintenance you will need to undertake will be regular ash removal (I would empty mine at least a few times each month during the winter), and making sure the area around it is kept clean. My system had a control panel that displayed any faults, so I would also check this on a regular basis.

Still wondering if a biomass boiler is right for you? Gordon Traill shares some final words of advice.

"I think basically anything that an oil boiler or an LPG boiler can do, a biomass boiler can do. It’s a high temperature heat source so it operates in the same way. Therefore, it's really a case of weighing up whether it's right for your situation.

"As they are on the expensive side, installing a biomass boiler is an ethical decision for people at the moment to reduce carbon emissions," he adds, "as it's still going to be better than fossil fuels.

"If you are considering where to invest your heating budget," says Gordon, "I always say the first money to spend in your heating scheme is on your home insulation and the fabric of the building. The benefit is, if you can do this, anything you install will work more efficiently.

"But, in those instances where you have a listed building for example, and sometimes not all the changes can be made, a biomass can be a good option as you will need a higher temperature heat source. After the initial investment, the running costs will always be lower than other fuel."

If you do live in a listed building and are considering all your renewable options, be sure to check out our guide to solar panels on listed buildings.

Get the Homebuilding & Renovating Newsletter

Bring your dream home to life with expert advice, how to guides and design inspiration. Sign up for our newsletter and get two free tickets to a Homebuilding & Renovating Show near you.

Tim is an expert in sustainable building methods and energy efficiency in residential homes and writes on the subject for magazines and national newspapers. He is the author of The Sustainable Building Bible, Simply Sustainable Homes and Anaerobic Digestion - Making Biogas - Making Energy: The Earthscan Expert Guide.

His interest in renewable energy and sustainability was first inspired by visits to the Royal Festival Hall heat pump and the Edmonton heat-from-waste projects. In 1979

this initial burst of enthusiasm lead to him trying (and failing) to build a biogas digester to convert pig manure into fuel, at a Kent oast-house, his first conversion project.

Moving in 2002 to a small-holding in South Wales, providing as it did access to a wider range of natural resources, fanned his enthusiasm for sustainability. He went on to install renewable technology at the property, including biomass boiler and wind turbine.

He formally ran energy efficiency consultancy WeatherWorks and was a speaker and expert at the Homebuilding & Renovating Shows across the country.