Building with structural insulated panels — everything you need to know if you're considering it for your self build home

Structurally strong, excellent for airtightness and quick to build, could a structural insulated panels construction method be the right one for your project?

Bring your dream home to life with expert advice, how to guides and design inspiration. Sign up for our newsletter and get two free tickets to a Homebuilding & Renovating Show near you.

You are now subscribed

Your newsletter sign-up was successful

If you’re planning a self build or extension project and researching build options, there’s a good chance you’ve come across structural insulated panels, also known as SIPs.

This build method has become popular with self-builders, especially those who want a home that’s quick to build, energy-efficient and strong enough to last a lifetime. But what exactly are SIPs, and how do they compare with the more traditional timber frame systems?

Whether you’re still weighing up your options or leaning towards SIPs but need that final reassurance, this article from self build expert, Mark Stevenson and architect, Allan Corfield, will help to inform your decision by explaining how SIPs work, their benefits and costs, and how they stack up against other timber systems.

What are SIPs?

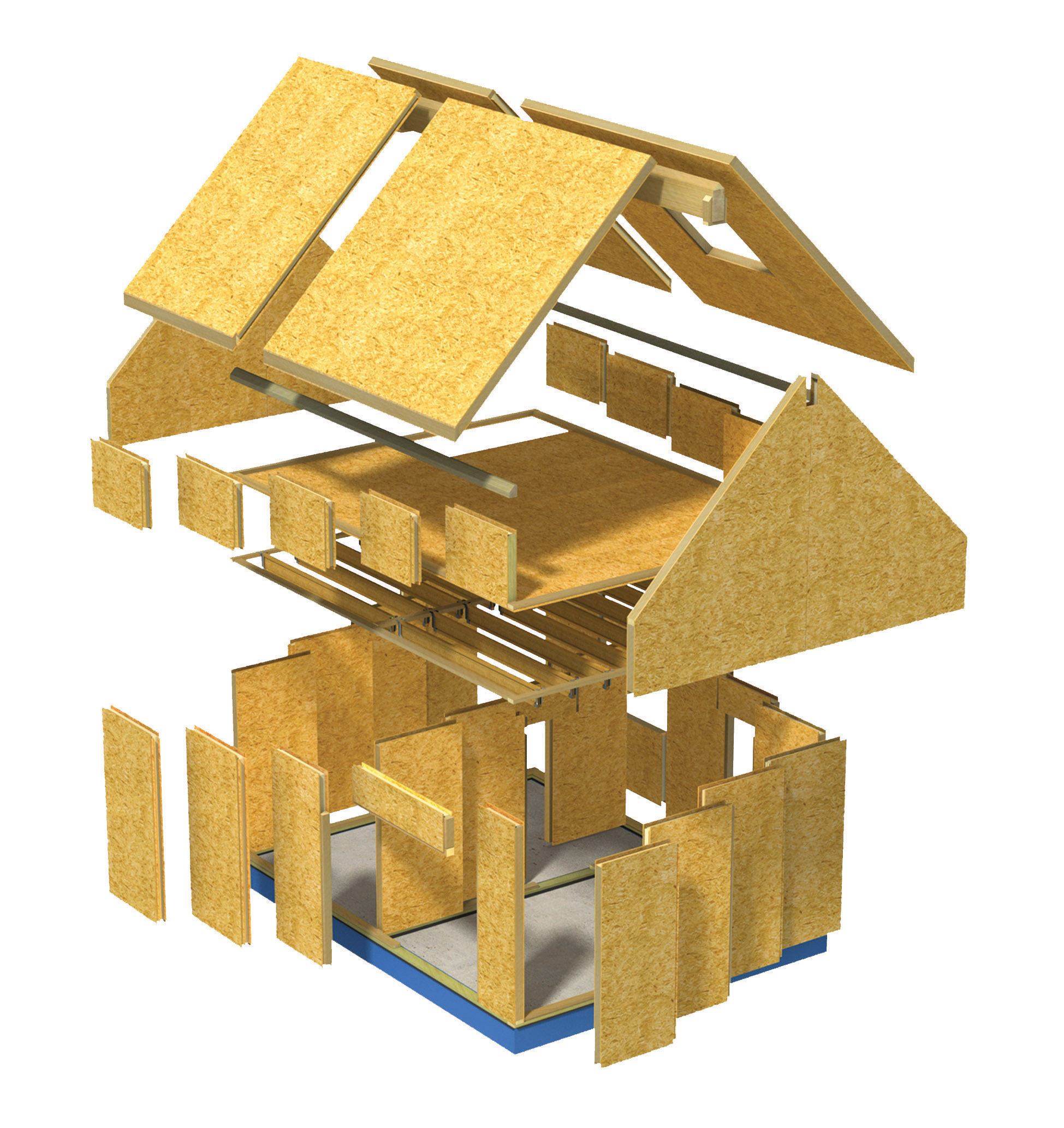

SIPs are essentially a sandwich – two layers of oriented strand board (OSB3) with a solid insulation core in between. Once bonded together, the panel becomes extremely rigid and strong, giving it both structural and thermal qualities.

These blank panels start their life in a 1.2m-wide format and come in various standardised heights from 2.4m to 7.45m.

The panels are then cut to size, timber edge pieces added and any openings formed. The same type of structural insulated panel is used for building the external walls, any internal loadbearing walls and the roof panels.

And, thanks to their precision manufacturing and robust jointing methods, they create a super airtight building envelope.

Bring your dream home to life with expert advice, how to guides and design inspiration. Sign up for our newsletter and get two free tickets to a Homebuilding & Renovating Show near you.

What sets SIPs apart from traditional timber frame construction is that they’re not just a frame filled with insulation – the insulation is structural. That means fewer air gaps, less thermal bridges, fewer weak points, and a structure that goes up fast and stays warm with a low energy input.

Types of SIP

There are two types of SIPs panels. Both use two OSB boards, but one sandwiches polystyrene board between them while the other has urethane pumped inside.

Both are wrapped in timber for strength, with depths of panels between 195mm and 250mm. The urethane method tends to make slimmer panels with slightly better thermal performance.

EPS panels range from 95 to 195mm (but can go much deeper, if required). The injected urethane core has a slightly better thermal performance, and therefore these panels tend to be smaller – with the larger panels being 172mm. Always go for the deeper panel if you are trying to create a low-energy home, with achievable U values going down as low as 0.13W/m2K.

All of the blank panels are surrounded by solid structural grade timber, giving the panels great stability and strength.

Joining SIP panels together

Most manufacturers use a ‘male to female’ timber stud to connect the panels to each other, and in most SIPs projects, two types of jointing are required.

For structural joints, such as where there is a structural steel, a lintel, or a spot load from a glulam beam, c24 timber is used to join the panels. Elsewhere, spline joints are used.

However, some manufacturers use a unique jointing system, which is made up from a mini panel. This can help with lowering the overall wall U value and minimise air leakage at the connection joints.

There are two main products:

- The first is a timber I-joist – these have a vertical web made from OSB and a top and bottom flange of solid timber

- The second is a posi-joist. This has the same solid top and bottom flange but with a metal vertical web.

Both products range from 200mm to 400mm deep (depending on the span) and are topped with a structural floor deck, giving rigid squeak-free floors up to 5m in width (without extra support).

SIPs vs timber frame construction

Most people are familiar with timber frame construction. It’s been used in the UK for decades, with modern versions including the insulation and membranes needed to offer a high-performance wall. Timber frame panels are usually assembled in a factory and delivered to site as closed panels – which means the insulation and vapour control layers are already in place, speeding up the build.

SIPs are, in many ways, an evolution of that idea. Rather than building a frame and then adding insulation into it, SIPs combine the structure and the insulation in one solid panel. This makes for a stiff, strong wall, with less structural timber and reduced risk of poor insulation installation as the insulation is fully bonded in the manufacturing process

One of the clearest advantages of SIPs is their airtightness. With traditional timber frames, it’s entirely possible to achieve a good airtightness result, but it requires a host of membranes, tapes and sealants and meticulous attention to detail. SIPs, on the other hand, are almost designed to be airtight by default, thanks to their bonded construction method and jointing systems that lock together tightly without leaving gaps.

Advantages of building with SIPs

One of the key benefits over traditional timber frame or modern closed timber frame systems is the spacing of the vertical timber studs within the walls. In a timber frame building these are at 600mm centres, while in a SIPs wall they are at 1200mm centres. Therefore the amount of poorly performing timber in the wall is halved. This dramatically reduces repeated cold-bridging in the building.

Factory-made SIPs panels will be more accurate than on-site cut timber frames, and this helps to limit gaps in construction. This, along with the inherent airtightness of oriented strand boards (OSB) and a rigid insulation core, helps to limit air leakage in the building, making SIPs a great fit for Passivhaus projects.

As the roof panels are structural there is also no need for traditional roof trusses – the panels can easily span 4.8m from eaves to ridge and sit on a boxed-in steel beam or a feature glulam timber beam. This can transform the top floor from a standard 2.4m floor-to-ceiling height, up to a double height of 3.6m.

Insulation and energy performance

If you’re building to meet – or beat – the latest Building Regulations, SIPs can make it easier. SIPs typically use polyurethane or polystyrene insulation cores with thermal conductivity as low as 0.024 W/mK. This means thinner walls can deliver impressive U-values – often around 0.15 W/m²K or lower and consistent across the whole structure.

If you’re aiming for Passivhaus or extremely low operational carbon targets, SIPs are very hard to beat. Their ability to prevent thermal bridging and achieve airtightness makes them ideal for anyone who wants a home that ‘sips’ rather than ‘gulps’, energy.

Carbon footprint

If sustainability is one of your key concerns – and for many self-builders, it is – SIPs are inherently low-carbon building systems. Timber is widely acknowledged as the most sustainable mainstream building material and compared to brick-and-block construction, its embodied carbon can be up to 82% lower. That’s a huge saving before you even switch on the lights.

In terms of operational carbon – the energy used to heat and run your home – SIPs offer a slight edge simply because of their performance. A SIPs home designed well, with high-performance windows and doors and mechanical ventilation with heat recovery (MVHR), has every chance of reaching ultra-low energy standards.

Are there any disadvantages to SIPs?

The main issue with SIPs is when they're exposed to moisture, and therefore there are some sites that don't suit a SIPs build. It's not recommended to use structural insulated panels on plots in flood zones or below ground, so here a masonry build would prevail.

However, there is nothing stopping you creating a hybrid build, with a masonry ground floor and SIPs for the upper storeys.

While the airtightness factor is a quality of SIPs, it also means you'll need to have adequate ventilation to avoid condensation building up and air becoming stale in the home.

You may also find that as SIPs are a specialist build system, you might find it harder to find builders who are experienced in using them.

How to design using SIPs

A SIPs designer will be armed with the right info about how to build a SIPs home and be able to design to the capabilities of the product, making sure you get the most for your money. Using an architect who has previous experience of designing with SIPs in mind will help make the process easier too.

Most construction products come in standardised sizes, so it makes sense to set out your design based around these. As the most common structural insulated panels come as 1.2m x 2.7m sheets, it also makes sense to utilise a 1.2m floorplan grid. That way you can lay out your walls along a grid, which will minimise the amount of cut panels. Every time the fabricator has to cut a section of a panel you will be charged for the labour time and for the disposal of the excess material.

The most common ground floor ceiling height is 2.4m, which can be created by using a 2.7m high panel with a 300mm floor joist hung from the top – giving 2.4m, which is also the size of a piece of plasterboard.

As you are creating an airtight fabric (aim for an air test value as low as 1.0m3/hour/m2), you need a ventilation strategy, such as an mVHR whole house system. The design and pipework integration has to be carefully considered with the floor joist layout.

Features such as glazed gables can also be added and the large opening is usually created by a steel frame that is fitted within the SIPs frame around the opening, then standard double or triple-glazed units are linked and stacked on top of each other. Ensure that your design team work closely with your frame and window supplier.

If large open plan, flexible spaces appeal, these are easy to accommodate within a SIPs home as well, due to the long spans of the floor joists and roof panels. The I-joist floor system can efficiently span 5m (300mm deep joists at 600mm centres). If you want a wider span, the most cost-effective solution is to integrate a steel beam, hidden in the floor build-up.

Building regulations and planning with SIPs

There’s often a misconception that planning permission can restrict what kind of building system you use – it can’t. As long as you meet the planning authority’s energy performance requirements and design criteria – usually related to appearance and scale – you’re free to choose the build system you like.

What you do need to ensure is compliance with Building Regulations. That means meeting structural requirements (Approved Document A) and energy efficiency standards (Approved Document L), among others.

SIPs are slightly more ‘novel’ in the sense that they have their own structural characteristics and performance data, so expect building control to ask a few more questions and request the proper calculations. Reputable SIPs providers will be used to this and can provide all the necessary documentation.

How long do SIP homes take to build?

One of the biggest appeals of building with SIPs is speed. Like timber frame, SIPs are factory-manufactured and delivered to site in panelised form. That means less time building on site, fewer delays due to weather, and a more predictable build schedule. For an average-sized house, the structural shell can usually be up and weather-tight within four to six weeks.

If you’re building in a location with poor access or limited space, SIPs can be delivered in smaller panel formats to suit. And for homes with rooms in the roof – rather than traditional trussed rafters – SIPs can make that process a lot simpler and quicker.

A typical two-storey 200m2 house could take just 12 days to factory fabricate and then 12 days to erect on site.

Compare this to a traditional timber frame construction which will take at least 3-4 weeks to get the frame erected. On average, building with SIPs is 55% quicker than a timber frame build.

This means savings on costs like scaffolding, plant hire and site insurance, bringing overall project costs in line with other build systems

Are SIPs expensive?

Comparing wall system costs, pound for pound, SIPs generally cost more than basic timber frame systems. But the gap isn’t massive – and when you factor in the performance benefits, reduced heating bills and speed of build, that extra investment may well be worth it.

Looking at project costs, a basic timber frame with brick cladding is treated as the 100% benchmark. A high-performance timber frame might be 107%, while a SIPs build with brick could come in around 116%.

Sounds expensive, but because the structure typically represents about 25% of the overall build budget, that difference only translates to about 3% extra on your whole project. For many self-builders aiming for long-term savings and better performance, it’s a price worth paying.

Myths and misconceptions

There’s still a bit of suspicion about timber systems, especially from those more familiar with masonry. But many of these doubts don’t hold up to scrutiny. For starters, all modern build systems – timber, SIPs, or otherwise – must comply with the same engineering standards. Timber homes are just as strong and arguably more resilient in high-wind areas thanks to their inherent flexibility.

As for fire safety, yes, timber burns – but so do many parts of masonry builds, including the floor joists and roof trusses. What matters is how the structure is protected, and both timber frame and SIPs homes are usually encased in plasterboard, stipulated by a fire test to prove the fire resistance and compliance with Building Regulations.

Concerns around rot are also overblown. Structural timbers are kiln-dried, treated, and kept on the dry side of the wall. As long as you build properly and maintain your home – especially cladding and roofing – timber buildings are very durable and will easily last a century or more.

There’s also a myth that SIPs homes are difficult to modify or extend. That’s only true if you don’t know what you’re doing. With proper guidance from the original manufacturer or a structural engineer, adapting a SIPs structure is completely manageable.

And for anyone worried about mortgages or insurance, these systems have been around long enough and are backed by certifications like BBA, LABC Assured, and STA Assure. You might have to dig a little deeper to find a lender who understands SIPs, but they’re out there – and if you’re working with a reputable manufacturer, they can often point you in the right direction.

Are SIPs right for you?

Choosing between SIPs and timber frame comes down to what you want from your build. If you’re looking for exceptional thermal performance, robust airtightness, and a system that gets you to Passivhaus standards, then SIPs are likely to be the better fit. They’re not always the cheapest, but they deliver long-term savings, comfort and sustainability that are hard to match.

For those focused on natural materials or looking to incorporate specific insulation types, a timber frame might offer more flexibility. But either way, you’re choosing a modern, sustainable system with a low carbon footprint and high-performance credentials.

FAQs

Are SIPs load-bearing?

Yes, structural insulated panels have two applications. First and foremost, they can be used as a full structural system for a build. Secondly, SIPs are also used for infill walling for steel, concrete, oak or glulam timber frame structures.

Can I use SIPs to build my extension?

SIPs can be used to quickly erect certain types of extension, however, when it comes to the cost implications, the savings made in time spent on site and being able to build in any weather are more substantial on a scaled up build, so when it comes to cost savings, traditional build methods are often still more affordable for smaller projects.

What external finishes can I use with SIPs?

As the panels provide the insulation and structure, there is no need for the external finish to provide any structural support, other than to support itself. This means that you can use modern, lightweight cladding systems, including timber, render board, rainscreen cladding systems or even stone/brick slips.

The chosen façade treatment is fitted via 50mm timber battens (required for ventilation) fixed to the outside of the kit, which will have been left with a breathable membrane. If you are going for a simple horizontal timber boarding, a competent DIYer could fit it themselves.

Heavier cladding options such as external skin of brick or stone will need to be built off their own foundations.

Services go in a service void, created with a 25mm x 50mm timber batten. This service void is wide enough to house your heating and electrical services, with larger pipes (such as MVHR or soil waste) located in internal timber stud walls.

How long will a SIPs home last?

Structural insulated panels have an estimated lifespan of 60+ years, while some of the first instances of SIPs builds are now 90 years old, they've only been in more common usage for the last three decades.

The final advice for building with SIPs? Make sure you get the right build team on board from the start. Interview various SIPs companies, choosing the company that gives a balance of value for money, quality product and assistance throughout the project. Try to work with a company that provides a total package: design, fabrication and site erection.

Work with design professionals who are used to working with SIPs and can maximise the benefits and help reduce the costs, and design efficiently, by working with standard panel widths and heights. This will give you the maximum building for your money.

And, before the breathable building paper is fitted to the outside of the kit, get your architect to ‘snag’ the building prior to releasing the final payment. This way any issues with the fabric can be identified and then corrected before your cladding ideas are applied.

Allan is a RIBA chartered architect and has overseen the design of over 350 low energy homes across the UK. He is one of the UK's leading experts on modern methods of construction including SIPs (structural insulated panels), is part of the Structural Timber Association, Passive House Trust and a member of the self build industry body, NaCSBA. He regularly contributes to Homebuilding & Renovating magazine and is a speaker and self build expert at the Homebuilding & Renovating Shows.

Since 2009, Allan has grown his custom and self build architectural practice, AC Architects, to a team of 16, and recently created AC Structures, a leading engineering business for self build projects.

Mark Stevenson is a construction professional with almost 35 years’ experience across housebuilding, timber systems manufacturing and bespoke residential development. He is the owner of Elsworth Projects Ltd, a consultancy specialising in the project management of bespoke self-build homes.

Previously Managing Director of Potton and former Chair of NaCSBA and the Structural Timber Association, Mark is widely recognised for his specialist knowledge of timber construction, land finding and appraisal, and the construction of self-build projects.

Alongside his professional career, Mark is a skilled joiner, hands-on renovator and serial self-builder. He regularly shares his knowledge at Homebuilding & Renovating Shows and coaches self-builders.