Underfloor Heating Manifolds: What do They do?

Underfloor heating manifolds are an essential part of your new underfloor heating system. Find out everything you need to know about them with this handy guide

An underfloor heating manifold is an integral part of your new underfloor heating (UFH) set-up, but for those who have never had a UFH system before, it's something you may not have come across.

In essence, a manifold is the control centre for your underfloor heating, allowing you to individually control the zones designed into the system, ensuring warm water flows to the spaces that need heating and not to those that don't.

It's likely that your underfloor heating manifold will be specified by your installer or the company you buy it from, but when it comes to designing your self build or extension with underfloor heating, it's important to keep some key things in mind when it comes to the manifold.

Here's what you need to know.

What is an Underfloor Heating Manifold?

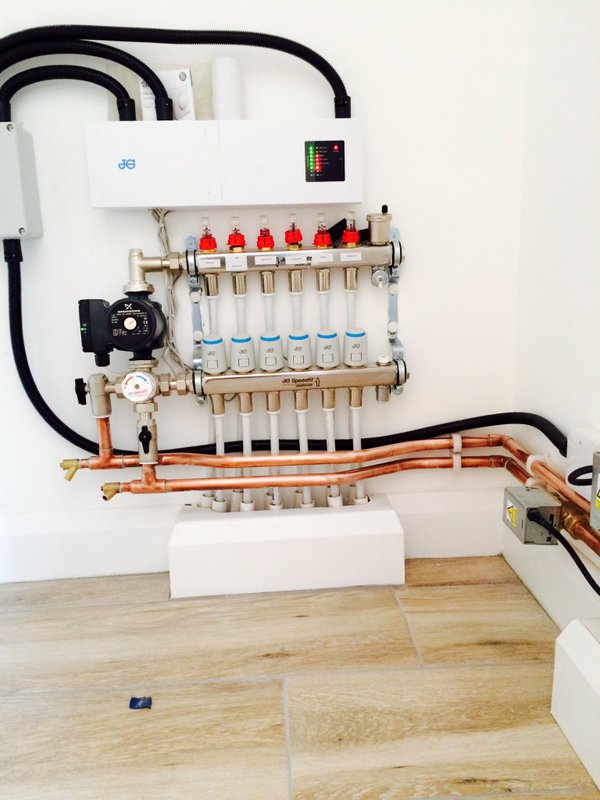

An underfloor heating manifold is effectively two rows of taps that allow water to flow to separate pipe circuits that are installed in separate areas (zones) in the floor so that those areas can be balanced and individually controlled.

The top row has adjustable valves that have a small transparent cap about the size of a thimble that shows the flow rate through it. As the valve is turned the flow rate will either increase or decrease allowing the system to have the desired flow rate in each circuit.

As an example you may have a 100m coil of pipe installed under the floor in the kitchen and a separate 80m coil of pipe in the dining room. The pipes will both come back to the taps on the manifold and adjustments can be made to make sure that there is an equal flow to each zone, due to the different pipe lengths, and there may also be a motor on the tap on the bottom row so that the zone can be turned off when heat is no longer required in that area.

How Does an Underfloor Heating Manifold Work?

The underfloor heating manifold features two solid bar pipes, with rows of taps on each. You can effectively have up to around 12 taps on each bar.

One bar has the water flowing to the zones and the other has the water flowing back from the zones. There is also a pump on the manifold that moves the water to the zones.

Next to the pump there is also a device that allows water to bypass the manifold if a lot of the zones are shut. A boiler needs a minimum flow rate in the heating circuit so some water needs to bypass the manifold if the resistance is high due to a lot of the taps being closed.

Key Components of an Underfloor Heating Manifold

The bar pipes could be up to around 800mm long and they are installed around 400mm off the floor.

Loops of special plastic pipe, often around 100m long are placed in the floor and the ends connected to a tap on each bar.

Also connected to the bar is a pump to circulate the water through the plastic pipes and a bypass valve (to ensure the correct water flow rate in the central heating circuit) and sometimes a blending valve that prevents the water in the floor from getting too hot.

Where Should an Underfloor Heating Manifold be Placed?

Underfloor heating manifolds can take up quite a lot of space and it is important that they are accessible for service and inspection. However, they're not the same as your heating controls, so they don't necessarily need to be located for everyday use.

Firstly, the position of the manifold must also be located in a position to allow for the separate zone pipes to all converge in that position without overheating the floor.

The second consideration is the proximity of the heat generator (boiler or heat pump) to the manifold. The further the heat generator is from the manifold the greater the potential of heat loss and also the harder it will be to route the pipes so that any heat loss does not conflict with the heating circuits or potentially crack or cause damage to the fabric of the building.

The manifold is a good candidate for inclusion in a plant room if creating one in a self build home, for example, but this may depend on the layout and proximity of other technology also required in the room.

How Many Underfloor Heating Manifolds do I Need?

It is usual to expect to have a separate manifold for each floor of the property.

If you have underfloor heating downstairs and radiators upstairs then you may not need a manifold for the radiator circuit if it is plumbed in a parallel configuration.

If you do choose a manifold for the radiator circuit then at least the motorised controls will be acoustically-isolated out of the bedrooms and not disturb anyone sleeping there.

(MORE: Choosing Radiators)

If the radiators are sized to operate at the same flow temperature as the underfloor heating then it is quite possible to combine radiators and underfloor heating circuits on the same manifold but care must be taken to balance the system as the radiators could have a lot less resistance than the underfloor heating circuits and therefore get the lions share of the heat, leaving the underfloor heating circuits feeling less than effective.

Specifying an Underfloor Heating Manifold

Underfloor heating manifolds can be purchased separately from the other components of an UFH system, but you must make sure that it is absolutely compatible with the pipework and all the other component, as well as the controls.

Some manifolds will have fittings that are designed for a specific type of pipe and may, therefore, not be compatible with other pipes.

It also needs to have the correct bypass and blending valves if the temperature needs to be controlled or limited. Your installer should be influential in helping make sure that the components all work together.

How to Install an Underfloor Heating Manifold

The water in a manifold is usually in a closed loop and is therefore covered by Part G of the Building Regulations which requires that the manifold is installed by an experienced and suitably-qualified professional.

You can have a say about where you would ideally like it located but the professional installer will ultimately need to make the design decisions and explain the best installation strategy and then install it in a safe and efficient location.

While the manifold needs to be installed by a qualified professional, laying the pipework is something that a competent DIYer could tackle.

Get the Homebuilding & Renovating Newsletter

Bring your dream home to life with expert advice, how to guides and design inspiration. Sign up for our newsletter and get two free tickets to a Homebuilding & Renovating Show near you.

David is a renewables and ventilation installer, with over 35 years experience, and is a long-standing contributor to Homebuilding and Renovating magazine. He is a member of the Gas Safe Register, has a Masters degree in Sustainable Architecture, and is an authority in sustainable building and energy efficiency, with extensive knowledge in building fabrics, heat recovery ventilation, renewables, and also conventional heating systems. He is also a speaker at the Homebuilding & Renovating Show.

Passionate about healthy, efficient homes, he is director of Heat and Energy Ltd. He works with architects, builders, self builders and renovators, and designs and project manages the installation of ventilation and heating systems to achieve the most energy efficient and cost effective outcome for every home.