Sanding wood: What you need to know to get the best finish

There’s an art to sanding wood, from choosing the right sandpaper grade, to selecting the best tools and applying the best techniques. Find out how in our guide

Sanding wood to a smooth, professional finish is all about appropriate preparation. It is a key component in ensuring that your wooden surfaces are ready for the next stage, whether that be painting windows, staining doors or varnishing table tops.

Different projects often embrace the same sanding processes, but there are subtle differences, techniques and tools that need to be used to ensure your wood is getting the love that it needs.

Here we look at how to sand wood for the best finish, including a deep dive into sandpaper grades and assessing which jobs are best tackled by hand or by power tool.

Sanding wood: Which sandpaper should I use?

When looking to sand wood there are a couple of considerations to think about. First there is the type of sandpaper you should use. The common choice, and typically the only choice you need for most DIY wood projects, is Aluminium oxide. When looking to purchase sandpaper you’ll notice that this is the popular choice and can be identified by its typically dark brown colour.

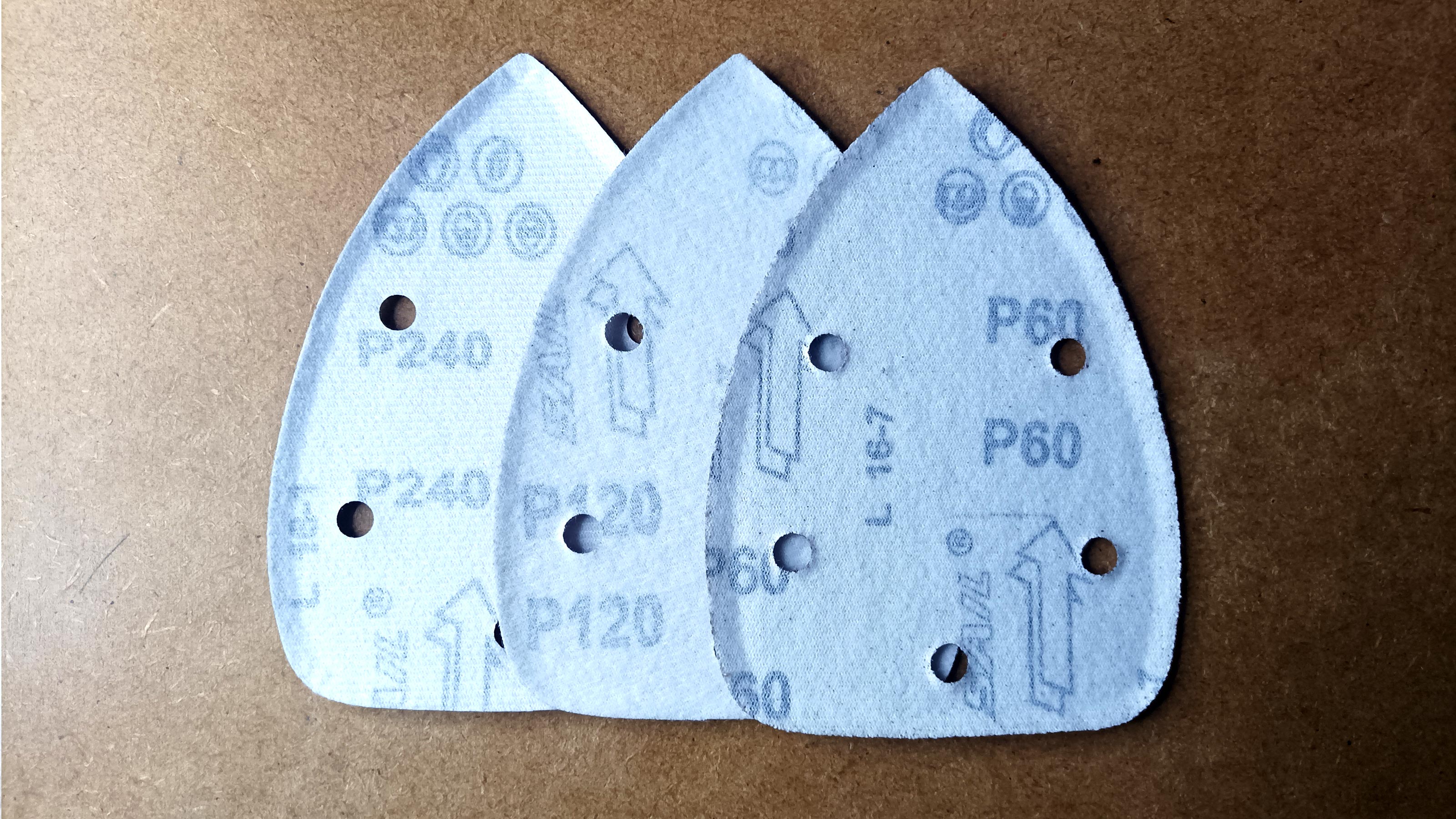

The more important consideration is the sandpaper grade or grit you need to use for a sanding job. Choosing the right one is essential to getting the right finish. Sandpaper is divided into grades, which encompass a collection of different grits. This is the number that you see on the back of the sandpaper.

As a general rule coarse sandpaper grades/grits are used to remove paint from wood or get rid of rough surfaces, while medium and fine grades are used for finishing ready for a top coat such as paint, stain or wax.

Here's the different sandpaper grades and grits to help you choose the right one for your DIY project:

1. Coarse sandpaper - up to 60 grit

This is good for removing old layers of paints and varnish and the aggressive nature of the grit means that you can get the job done pretty quickly especially if you use the best orbital sanders, or other power sanders.

2. Medium sandpaper - 60-100/120 grit

This is a good choice for bare wood finishes such as coarse cut timber, wood that has been stripped and needs to get rid of leftover paint, and rubbing down previously painted woodwork ready for painting.

3. Fine sandpaper - 120-220 grit

This is a commonly used grade in a lot of home DIY projects, especially painting projects such as painting skirting boards, windows and doors. 120-180 grit is ideal for sanding down previously painted surfaces that don't need a lot of work.

It gets rid of minor imperfections and improves adhesion for new paint. 220 grit is often a good choice to finish up wood ready for varnish or stain and rubbing down filler on walls.

Do I need extra fine or extra coarse sandpaper?

Extra fine and extra coarse grits are only used for more specialist jobs and typically you will rarely need them. Girts above 240 can be used between coats of paint to help get a super smooth finish. Extra fine grits like 400 are used to get a really fine finish on wood for waxing and polishing. Grits below 40 only need to be used on wood that has a lot of paint or varnish to be removed.

Should I sand by hand or use a power sander?

This depends very much on what wood you are sanding and what project you are working on. Below we explain the situations when you might sand wood by hand versus picking up the power tools.

1. Sanding wood by hand

Sanding wood by hand gives you fine control over the sanding process for a more precise and refined finish. It's good for sanding large flat areas if you have the help of the right tools such as a hand sander, a sanding block like the SATC Hand Sanding Block from Amazon or a piece of the right size scrap wood to wrap the sandpaper around. This helps keep the sandpaper flat on the surface and allows you to apply more or less pressure.

For harder to reach areas such as mouldings or architrave sanding by hand is your only real option. Sanding sponges are a good choice for this type of work as they mould to the shape of the wood. Check out our Sanding wood by hand guide for more insight.

2. Sanding wood with a power sander

Using a power sander on wood is a quick and effective way to get the smooth surface you want on a project. They are great at getting rid of unwanted layers of paint and varnish and giving a silky smooth finish ready for painting, varnishing or staining. There are different types of sanders for different projects with orbital sanders being a popular choice due to their versatility and ability to get a good finish. Check out our guide on how to use an orbital sander to get the best from one.

One downside is their round sanding pad which makes them a poor choice for corners. A detail sander like the BLACK+DECKER Detail Mouse Electric Sander from Amazon is an ideal choice for corners thanks to its triangular sanding pad. But these can still leave sanding marks, so for fine finishes it's still a good idea to finish sanding by hand.

In what order do you sand wood?

This depends on the state of the wood you are sanding but as a general rule you should start out with a coarse grade sandpaper before progressing to a fine grade sandpaper to finish. This helps sand out any marks left by the larger grits.

For example, if you are sanding doors that have a lot of old paint on them you want to start out with a 60 grit to remove most of the paint, before progressing to a 120 grit sandpaper and finishing off with a 180 grit. This progression will vary depending on the original state of the wood and the finish you are looking for.

How can I tell if the wood is sanded enough?

There are a few tips and techniques you can use to help you decide on whether or not you have sanded your wood enough. The easy option is to run your fingers over the sanded surface and make a judgement call. This will help determine if the surface is smooth enough and identify any imperfections.

To ensure that you are sanding the surface flat, gently draw pencil marks across the whole surface. When the marks are gone move to the next section and repeat until all the pencil marks are gone.

Finally, while the surface of your wood may look smooth and scratch free, it may be hiding some unseen marks. Get a damp cloth and wet the wood to see if any marks appear on the surface.

Get the Homebuilding & Renovating Newsletter

Bring your dream home to life with expert advice, how to guides and design inspiration. Sign up for our newsletter and get two free tickets to a Homebuilding & Renovating Show near you.

Steve Jenkins is a freelance content creator with over two decades of experience working in digital and print and was previously the DIY content editor for Homebuilding & Renovating.

He is a keen DIYer with over 20 years of experience in transforming and renovating the many homes he has lived in. He specialises in painting and decorating, but has a wide range of skills gleaned from working in the building trade for around 10 years and spending time at night school learning how to plaster and plumb.

He has fitted kitchens, tiled bathrooms and kitchens, laid many floors, built partition walls, plastered walls, plumbed in bathrooms, worked on loft conversions and much more. And when he's not sure how to tackle a DIY project he has a wide network of friends – including plumbers, gas engineers, tilers, carpenters, painters and decorators, electricians and builders – in the trade to call upon.