Is underfloor heating the right choice for your renovation? We explore the pros, cons and potential costs

While retrofitting underfloor heating may feel like a modern energy-efficiency upgrade, when might you be better spending your budget elsewhere?

Bring your dream home to life with expert advice, how to guides and design inspiration. Sign up for our newsletter and get two free tickets to a Homebuilding & Renovating Show near you.

You are now subscribed

Your newsletter sign-up was successful

Underfloor heating has become almost the de facto standard for the self-builder, and putting it into a new build is simple, effective, relatively cheap and adds a touch of luxury.

After all, who doesn’t enjoy the feeling of walking over a warm floor, not to mention having walls that are suddenly free of radiators? But, can the same be said for a renovation project?

Renovation does not offer the same blank canvas and there will always be issues and problems to overcome which may make you question your decision. Build experts Tim Pullen and Ian Rock explain when it works, and when it might be worth considering an alternative type of heating emitter instead.

Factors to consider when retrofitting underfloor heating

The holistic view of renovating a house starts with what best suits the house. What the people living in it want obviously counts, but if it feels like installing underfloor heating will mean it is being shoe-horned in, then it probably should not be done.

It is a matter of considering the four key issues: the heat source, the hot water cylinder (if present), the existing floor and the level of insulation and airtightness achievable for the house as a whole. Ask yourself these questions:

- If the boiler needs to be replaced, is a heat pump an option?

- Is there budget available for a thermal store?

- Can the existing floor be retained or must it be removed and reinstated?

- Can insulation and airtightness be brought to, at least, current Building Regulations standard?

If all these stars align then retrofit underfloor heating is an option. If not then choosing radiators may be a better bet for your project.

Cost implications of retrofitting underfloor heating

There are a few situations that dictate that UFH cannot be installed and fewer that dictate that it must be installed.

Bring your dream home to life with expert advice, how to guides and design inspiration. Sign up for our newsletter and get two free tickets to a Homebuilding & Renovating Show near you.

The only issue that genuinely prevents UFH being installed is underfloor heating costs. Conventional UFH systems can be over 125mm thick and that can mean removing and reinstating the floor to maintain a reasonable floor-to-ceiling height.

Low-profile, or overlay underfloor heating systems can be as little as 15 or 22mm which usually overcomes the problem but there are, albeit rare, occasions when even that has an impact.

That is not to say that it should be installed. Almost invariably, installing underfloor heating will be more expensive than in a new build, as there will be preparation work and that will have a cost – floor coverings need lifting, skirting boards and doors removing and, unless a low profile system is selected, floors may need excavating.

Another issue is thermal efficiency. UFH operates just a few degrees above the desired room temperature and is therefore best suited to well-insulated properties. Poorly insulated or draughty properties need more heat and therefore a larger UFH system. That not only increases installation cost but also running costs, potentially to the point where radiators would be a better option from a financial standpoint.

It is fair to say that the bigger the renovation project the more likely it is that UFH will be suitable. If the ‘renovation’ planned is little more than redecoration, it is probable that the disruption, installation and running costs would make UFH a poor choice.

Wet or electric UFH when retrofitting?

These are distinctly different systems with different applications. Electric underfloor heating is cheaper and easier to install than wet UFH and much thinner, so there is a role for electric UFH in small, difficult-to-access rooms.

But it is relatively expensive to run. A kilowatt of heat needs a kilowatt of electricity, and electricity is more than 3 times the price of gas if you compare the unit cost per kWh.

Although the efficiency of heat pumps means that in well-insulated properties they can cost less to run than gas boilers, it wouldn’t make sense to fit electric UFH throughout the house. If that is the only UFH option then radiators would be the better choice.

Easiest type of underfloor heating to use when renovating

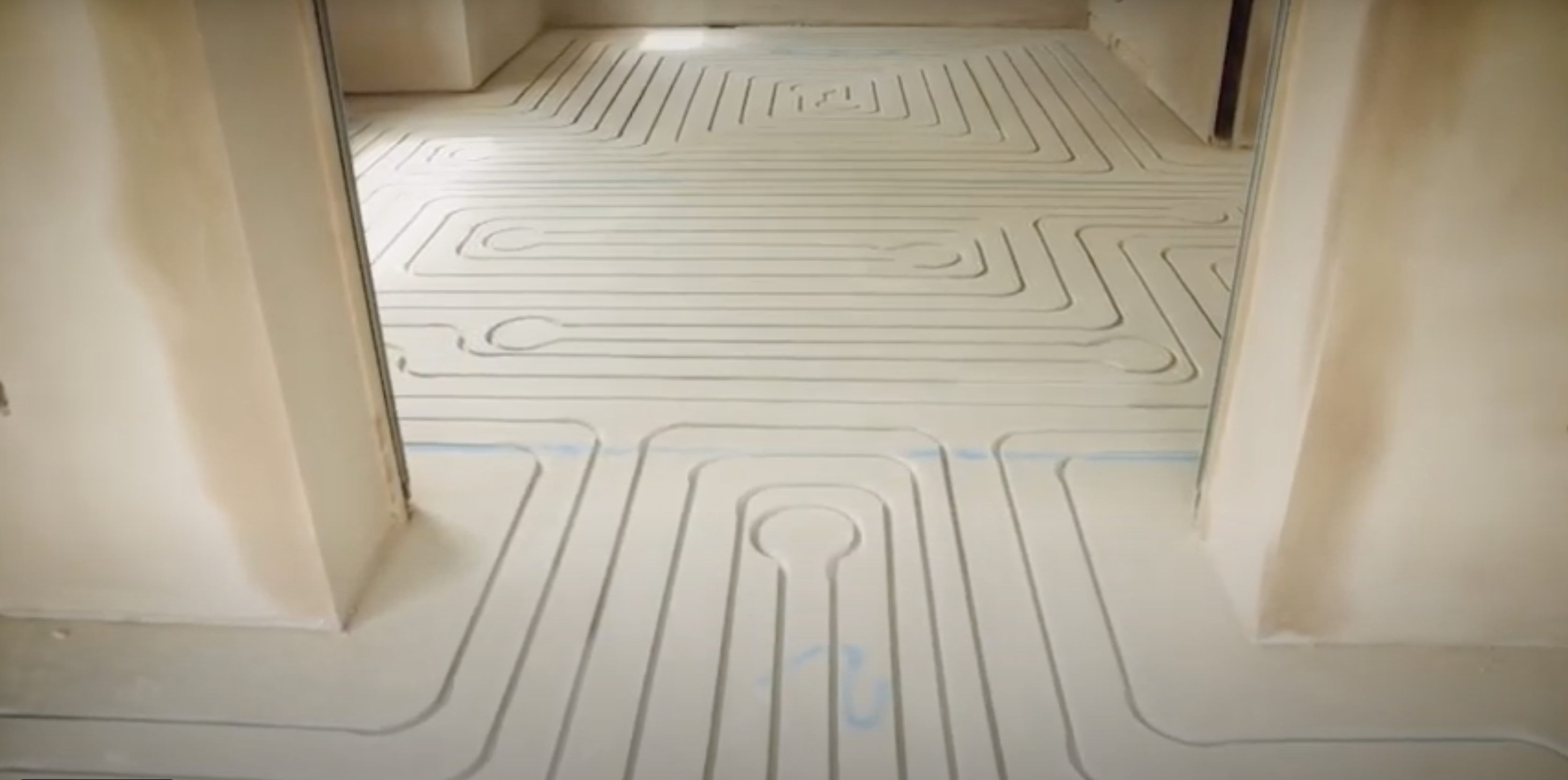

The simplest and least expensive method for installing UFH in renovation projects is to use a specially designed low-profile system. Rather than laboriously excavating and reconstructing the floor these are designed to be installed over existing subfloors with minimum disruption.

Pipes are looped through special castellated plastic panels laid over the floor surface, onto which a self-levelling floor compound is then poured. Depending on which system you specify this should only raise the finished floor level by around 15 to 30mm. Floor coverings can be laid after about 72 hours. Some flooring finishes can be laid over the panels without the need for any screed.

The main potential drawback is the lack of insulation, so it’s important that the system is designed to accommodate the resulting heat loss (more of a concern with older solid ground floors than suspended timber which can be insulated between joists). The designer will need to factor in each room’s heat losses, taking into account the flow rate and the desired room temperature to provide the right level of warmth.

Leading suppliers such as Nu-heat and Wunda provide custom low-profile kits; so the likely cost for a living room of 20m2 floor area would be in the region of £1,000 plus labour. Most systems are DIY-friendly, although you normally need a heating engineer to install the manifold and smart controls, as well as for connecting it up to the heat source and commissioning.

Raising floor heights by such a small amount shouldn’t cause too many issues other than adjusting items of joinery etc, and can be mitigated further if new floor coverings are slimmer than the old ones.

Probably the most important area to check is the staircase, because unless each step has the same riser height it can potentially become hazardous. Problems can also arise where one room has a higher floor level than adjoining rooms.

Removing floors

Often the big issue for UFH in renovation projects is how to cope with the existing floor. Should you put the UFH on top of the floor, or under it? Or should you rip everything out and start again?

This last option is expensive but allows space for insulation and for the finished floor surface to match the level of the existing floor. If floorboards can be removed then it is entirely possible to suspend UFH between the joists and retain the existing floor level, as would be done for a first floor.

Concrete floors are trickier to deal with, and if the UFH has to go on top. There are systems like Nu-Heat LoPro that claim to raise the floor level by as little as 15mm and cost significantly less than the excavation and rebuild method.

Insulation requirements when retrofitting

In a new build we would be required to install at least 100mm of rigid foam insulation (Kingspan, Celotex or similar) to meet the building regulations’ requirement to achieve a U-value in the floor of 0.13W/m2 K.

In a renovation the regulations are more relaxed, if they apply at all, and less insulation is permissible. A point to consider is that the ground under the floor will typically be 10°C to 12°C all year round. The lower internal/external temperature difference means that less heat will be lost through the floor than through the walls or roof.

In running cost terms, the difference between ideal insulation and minimum insulation is not huge, although some insulation is better than none. That said, there are UFH systems that use no insulation at all. For example grooves can sometimes be cut into existing concrete floors to accept the pipes, allowing the floor finish to go straight on top, not raising the floor height at all.

The reasoning is that only 10% of the heat in the house escapes through the floor so insulation is not really necessary. However, that is 10% of the heat in an uninsulated house. If the walls, loft, windows and doors are all properly insulated then the proportion of heat escaping through an uninsulated floor will increase to over 50% (of a much lower total).

Screed and backing boards

The point of UFH is that the floor essentially becomes the radiator. Therefore there needs to be something that spreads the heat from the pipes evenly across the whole floor.

The conventional solution to this problem is a sand and cement screed, typically 75mm thick. It needs to be that thick to prevent cracking, but consequently it is expensive, it takes weeks to properly cure and it gives a reaction time (that is, the time taken to warm the room) of up to four hours.

It can be argued that every UFH system would be better with a liquid flow screed. These can be as little as 25mm thick (although 30mm to 45mm is more usual), can be walked on 24 hours after laying, have better thermal conductivity and a reaction time as low as 30 minutes.

If the UFH is going on top of a timber subfloor, then there is also a weight issue to consider. In such cases it may be better to use a backing board.

Insulated backing boards, pre-grooved to accept UFH pipes, are readily available and are often used in conjunction with an aluminium spreader plate, which is heated by the pipes so that it can in turn distribute the warmth across the whole floor.

There is some discussion about exactly how efficient aluminium is as a heat diffuser, but the technology has become common and convenient, so for now it’s the best option, especially as it allows the floor finish to be laid directly on top of the original timber floor while applying only a minimal load.

FAQs

Which heat source is best?

Wet UFH will run with any heat source: gas or oil boiler, air or ground source heat pump. Heat pumps work most efficiently when delivering low temperature water and so UFH and heat pumps are well paired.

Typical radiators need water at up to 65˚C and UFH only needs water at around 40˚C. Heat pumps can run radiators but they need to be larger than normal or low-flow rate, high-efficiency radiators.

In reality the heat source is less important than the hot water cylinder. A good thermal store will deal with the water delivered by any heat source and efficiently deliver water at the right temperature for UFH, radiators and taps.

Before you retrofit underfloor heating, make sure you also know what's involved with underfloor heating maintenance, and be aware of the underfloor heating mistakes you need to avoid for your system to perform at its best.

Tim was an expert in sustainable building methods and energy efficiency in residential homes and wrote on the subject for magazines and national newspapers. He is the author of The Sustainable Building Bible, Simply Sustainable Homes and Anaerobic Digestion - Making Biogas - Making Energy: The Earthscan Expert Guide.

Tim's interest in renewable energy was first inspired by visits to the Royal Festival Hall heat pump and the Edmonton heat-from-waste projects. Moving to a small-holding in South Wales fanned his enthusiasm for sustainability. He went on to install renewable technology at the property, including biomass boiler and wind turbine.

He formally ran energy-efficiency consultancy WeatherWorks and was a speaker and expert at the Homebuilding & Renovating Shows across the country.