Mineral wool vs fibreglass insulation — how to choose between these for your project

When adding insulation to your build, both mineral wool and fibreglass are go-to options. Here we look at how to choose between them

When deciding between mineral wool and fibreglass insulation, the choice can be tricky, as on initial inspection both can look similar.

However, while both are popular for home insulation, they offer different advantages depending on your project’s needs. Whether you’re insulating a loft, walls or floors, understanding their characteristics can help you make the best decision.

Here we look at several aspects of both mineral wool and fibreglass insulation, including composition, ease of use, thermal performance, lifespan and durability as well as fire resistance to help you make a decision on which to choose.

Composition

What is mineral wool insulation?

Mineral wool, made from natural stone, is recycled slag (a by-product of steel production), or silica, and is manufactured by melting these materials and spinning them into fibres.

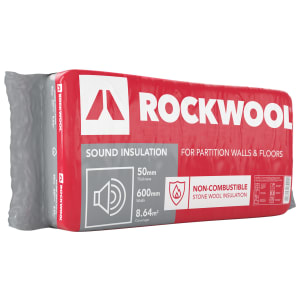

Sometimes called stone wool, it’s dense, durable and offers good thermal, acoustic, and fireproofing properties. You’ll often find it used in more heavy-duty settings, like industrial applications, but it’s just as suitable for residential projects where high performance is needed.

What is fibreglass insulation?

Fibreglass insulation on the other hand, is made mainly from recycled glass, which again is melted and spun into fibres, creating a wool-like material.

This type of insulation, sometimes called glass wool or even glass mineral wool, is the classic insulation quilt most people are familiar with, often sold in rolls or pre-cut batts. Because it’s lightweight and affordable, fibreglass is popular for DIY projects like insulating lofts or insulating a wall.

Bring your dream home to life with expert advice, how to guides and design inspiration. Sign up for our newsletter and get two free tickets to a Homebuilding & Renovating Show near you.

Application

Mineral wool is versatile and can be used in various settings, including floors and. walls, for insulating roofs, and even around pipes. Its density makes it particularly good for situations where fire safety and soundproofing are essential.

Fibreglass is used widely in homes and is commonly used to insulate attics, ceilings and for internal wall insulation. It offers good thermal and acoustic insulation, but some argue that it’s not quite as robust as mineral wool.

Ease of use

If you’re handling the installation yourself, fibreglass is probably the more straightforward option. It’s lighter and more flexible, so it’s easier to cut and fit, especially into irregular spaces and around services etc. However, the tiny glass fibres of fibreglass insulation can irritate your skin, eyes, and lungs. So, make sure to wear proper protective gear.

Mineral wool, due to its higher density, is heavier and stiffer, which can make it harder to work with. But, because it holds its shape so well, it’s better for vertical installations like wall cavities, where it won’t sag over time.

Thermal performance

When it comes to keeping your home warm, both mineral wool and fibreglass perform well. However, mineral wool is slightly more efficient at maintaining warmth due to its thermal resistance and density, which means it might take less material to achieve the same level of insulation.

That said, both materials have improved in recent years, and with the right thickness and density, fibreglass can offer similar thermal performance to mineral wool. In quilt form, both offer a thermal conductivity performance of around 0.044 W/mk, which can be as low as 0.032 W/mk when made into dense batts.

Soundproofing

If sound insulation is your priority, mineral wool is the better option. Its dense structure makes it more effective at absorbing sound and reducing noise transmission. This makes it a popular choice in buildings where acoustic performance is important, such as between floors or in walls separating rooms. Fibreglass also provides decent soundproofing, but it’s not quite as effective as mineral wool.

The Building Regs requires a 45-decibel reduction in airborne sound transmission between habitable rooms in domestic dwellings, and both insulation types can meet the 10kg/m3 density required to achieve this.

Fire Resistance

Fire safety is a key consideration in any building, and both mineral wool and fibreglass are non-combustible. Mineral wool, however, has a higher fire resistance – it can withstand temperatures up to 1,000°C. Fibreglass, while still fire-resistant, starts to melt at around 600°C, so doesn’t offer quite the same level of fire protection as mineral wool.

Whilst this all sounds impressive, both insulation products must function as part of a complete system to offer a fire resistance. If you need a specific fire performance, you’re therefore more likely to be choosing a fire tested system rather than an individual insulation product.

Lifespan and durability

Both mineral wool and fibreglass have long lifespans, typically lasting around 50 years or more, if installed and maintained properly. However, mineral wool’s resistance to moisture gives it an edge in durability. It’s less likely to lose its shape or performance over time, especially in areas prone to dampness.

Fibreglass, particularly in its quilt form, is more prone to sagging and moisture absorption, which can reduce its effectiveness over time. If you’re installing insulation in an area where moisture is a concern, mineral wool might be the better choice for long-term performance.

Price

For budget conscious self-builders, cost is always a factor, and fibreglass is generally the more affordable option. Depending on the brand and type, fibreglass insulation can be up to 40% cheaper than mineral wool. Mineral wool’s higher price is justified by its superior fireproofing, soundproofing and moisture resistance, but if these factors aren’t so essential, fibreglass is often the more cost-effective option.

How to choose between the two types

Ultimately, the best insulation material for your project depends on your specific needs and budget.

For cost-effective, DIY-friendly insulation: Fibreglass tends to be cheaper than mineral wool and effectively does much the same job. It’s affordable, easy to handle, and provides good thermal insulation, making it ideal for projects like loft insulation, or acoustic insulation in ceilings or wall.

For superior fireproofing, soundproofing, and durability: Mineral wool is worth the extra cost if you need improved performance. It’s especially suitable for applications where fire safety is a concern, or where noise reduction is critical, such as family homes with teenage kids!

If you are looking for either natural insulation or eco insulation types, consider looking at wood fibre insulation, hemp insulation or sheep wool insulation.

However, it is worth bearing in mind the thickness requirements for thermal performance to satisfy building regulations when making a choice. You can read more in our article on how thick should loft insulation be.

Mark Stevenson is a construction professional with almost 35 years’ experience across housebuilding, timber systems manufacturing and bespoke residential development. He is the owner of Elsworth Projects Ltd, a consultancy specialising in the project management of bespoke self-build homes.

Previously Managing Director of Potton and former Chair of NaCSBA and the Structural Timber Association, Mark is widely recognised for his specialist knowledge of timber construction, land finding and appraisal, and the construction of self-build projects.

Alongside his professional career, Mark is a skilled joiner, hands-on renovator and serial self-builder. He regularly shares his knowledge at Homebuilding & Renovating Shows and coaches self-builders.