I installed MVHR and it has completely stopped condensation in my home

Energy expert David Hilton installed mechanical ventilation heat recovery (MVHR) into his existing home three years ago, and he says it was one of the best decisions he ever made

Whether you’re a self builder or renovator, it’s likely given the current energy crisis that energy efficiency will be high on the priority list for your home. This has always been the case for me too, and upon installing MVHR in my home it became an unexpected solution for removing condensation.

Before embarking on the extension and renovation of our property — where we have lived as a family for about nine years — during each winter there would be lots of humidity and moisture on the inside of the windows. Inevitably they would need ongoing cleaning and redecoration due to the moisture damage as well as the use of many chemical products to mitigate mould growth.

Since installing mechanical ventilation heat recovery (you can check out our MVHR explainer for more detail on what it is) three years ago, there has been absolutely no moisture on the windows and a much more comfortable air quality in the house. This included the years of lockdown where there was a much higher occupancy and therefore more moisture produced.

From the initial decision-making process to installation, this is what it’s like living with installing and living with MVHR in an existing home (in my case, a 1980s bungalow) and what you can expect at each step of the way.

When did I first consider installing MVHR?

MVHR works by extracting air from a room and replacing it with a similar volume of warmed air. If you can imagine a situation where a room is very leaky, the extraction will draw in cold, outside air, outweighing the value of the warmed air being introduced. So there is clearly a level of airtightness at which MVHR will start to be effective.

When thinking of all the details required for an extension to our 1980s home, an MVHR system was not an obvious addition to the list. It was only because I have installed these systems myself that I thought it may be an option.

When I asked around in the industry the general opinion was that they should only be included in new build properties, and because older properties are generally not very airtight, it was deemed as impossible to make it work.

From my years in the industry, though, I was not convinced, and as I like a challenge I decided that MVHR was definitely going in.

How much does MVHR cost to install?

As someone who installs energy-efficient home solutions for a living, I was in the fortunate position of being able to install our MVHR system myself, which eliminated the cost of hiring someone in to do it. This won’t be the case for the majority of renovators and home improvers, even those who are DIY savvy.

The cost of materials for a decent fan unit and good quality ducts is going to be around £3,000 for homes around 180m2. This can vary from home to home depending on the number of rooms and valves.

Installation could also be between £2,000 and £3,000, so there could be savings to be made if you install it yourself. Getting it all balanced and commissioned is also around £350 to £500.

That’s a total figure of around £6,500, which you’ll have to factor into any MVHR installation plans you have.

What was it like to install in an existing home?

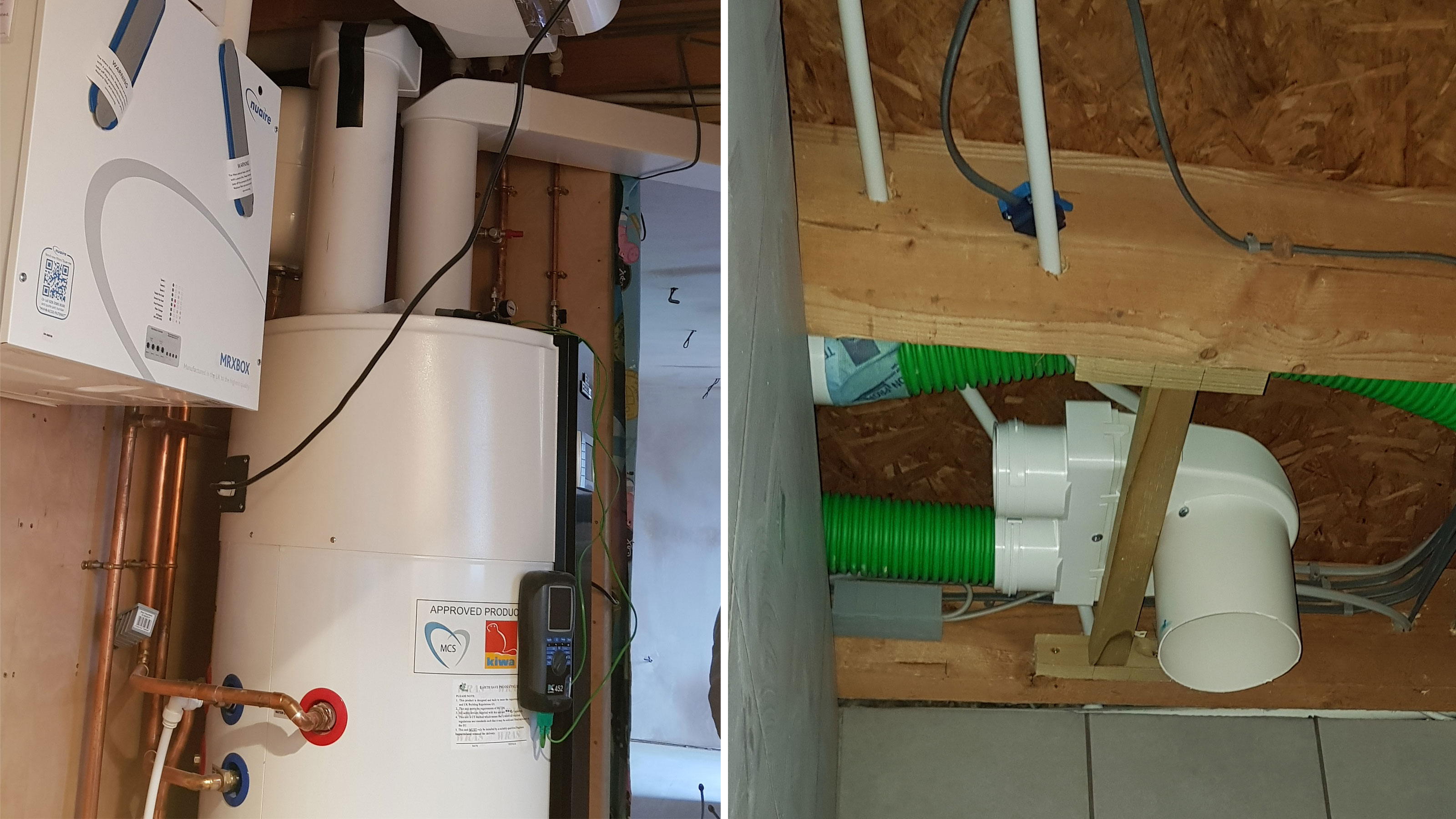

Because our home was not actually very airtight (even though we did deal with many air gaps and insulation cold spots), I changed the traditional MVHR design methodology and put an inlet and extract valve in every unique area (room or open plan space). This way, each area would be balanced and any lack of airtightness would not affect the air flow.

This also meant that I did not have to allow for any gaps at the bottom of the doors for circulation.

MVHR systems have the facility for two filters, which are usually dust filters, but as we live near a road and also experience a high pollen count at certain times, I decided to add additional filters to the inlet air ducts to filter out pollen and NOx fumes (car exhaust). This was the easy bit.

The real challenge was designing and planning where all the ducts and boxes went, bearing in mind that with the additional valves come additional ducts. There are a number of different types of ducts and we used a combination of almost all of them.

The main semi-rigid radial ducts have an outer diameter of 76mm so you need around 78mm holes through structural elements. The duct comes in 50m coils so it is possible to pull them through some tight areas.

I would suggest that ducting is best done by a local installer as there may be many visits to do small amounts of work as the project progresses and different areas of the home get opened up. You only get one chance at this because hiding the ductwork away can be a major challenge at the best of times and very difficult in a finished home.

But it is possible to install the ducts yourself, or to get one of your builders to do this, if you’re working on a renovation. It's not a difficult task but it does take time. You cannot drill through solid joists or rafters so planning is vital. It is also crucial to make sure that noise cannot move between rooms through the ducts.

One thing in our favour was that our home is a bungalow with a loft conversion so there was some space in the eaves for ductwork and two of the joist channels were open as well, which allowed for the radial ducts to pass through.

Another big challenge was that the fan unit is sited in a utility room, in an area of the home with a flat roof and solid joists spanning in the wrong direction. The only way to get things in place was to use different flat ducting and drop the ceiling by 80mm.

Can a cooker hood be connected with an MVHR system?

Any existing extract vents in the bathrooms were removed because the MVHR is on 24 hours a day. We did keep the cooker hood in the kitchen, however.

There are two options when it comes to your cooker hood. You can either use a cooker hood that has filters and recirculates the air back into the room, or if the kitchen is not too small then you can keep the extracting cooker hood but know that when you run it you will not be recovering any of the heat in the expelled air. You can check out some of the best cooker hoods in our cooker hood guide.

A cooker hood expels air at between 30 and 60 litres per second when it is running and an MVHR system only moves around 13 litres per second when in boost mode, albeit that it does run 24 hours a day. If you need faster air extraction while cooking then you may want to keep the cooker hood and take the hit on efficiency.

You just need to be sure that when the cooker hood is running that it does not suck air backwards through the ductwork.

How has the MVHR performed?

The savings on your energy bill will have a direct relationship to the airtightness of your home, but for us there is no real calculable payback on our system as it is difficult to know what the ventilation rate was before we started.

We know that we save at least 75% of the heat in the ventilation air, and that is a good thing, but the biggest win for me is knowing that the home is now correctly ventilated and the fresh indoor air quality means that the home and the occupants have a much healthier environment

MVHR was one of the unexpected success stories of our renovation project. I had no intention of putting it in but for some reason I did.

We have had zero moisture on the windows in the last three years, and the heat recovery element is also performing better than expected.

On many evenings, when it is an ambient temperature of -1°C outside and an average temperature of 19°C in the home, we will see the temperature of the incoming fresh air at around 16°C.

Get the Homebuilding & Renovating Newsletter

Bring your dream home to life with expert advice, how to guides and design inspiration. Sign up for our newsletter and get two free tickets to a Homebuilding & Renovating Show near you.

David is a renewables and ventilation installer, with over 35 years experience, and is a long-standing contributor to Homebuilding and Renovating magazine. He is a member of the Gas Safe Register, has a Masters degree in Sustainable Architecture, and is an authority in sustainable building and energy efficiency, with extensive knowledge in building fabrics, heat recovery ventilation, renewables, and also conventional heating systems. He is also a speaker at the Homebuilding & Renovating Show.

Passionate about healthy, efficient homes, he is director of Heat and Energy Ltd. He works with architects, builders, self builders and renovators, and designs and project manages the installation of ventilation and heating systems to achieve the most energy efficient and cost effective outcome for every home.