How to draught proof sash windows to keep out the chill

If you are wondering how to draught proof sash windows then our guide will be just what you need. We look at the DIY approach as well as methods used by the pros

Making the decision to draught proof sash windows is one of the best things you can do to save money on your energy bills — as well as ensuring your home feels warm and toasty.

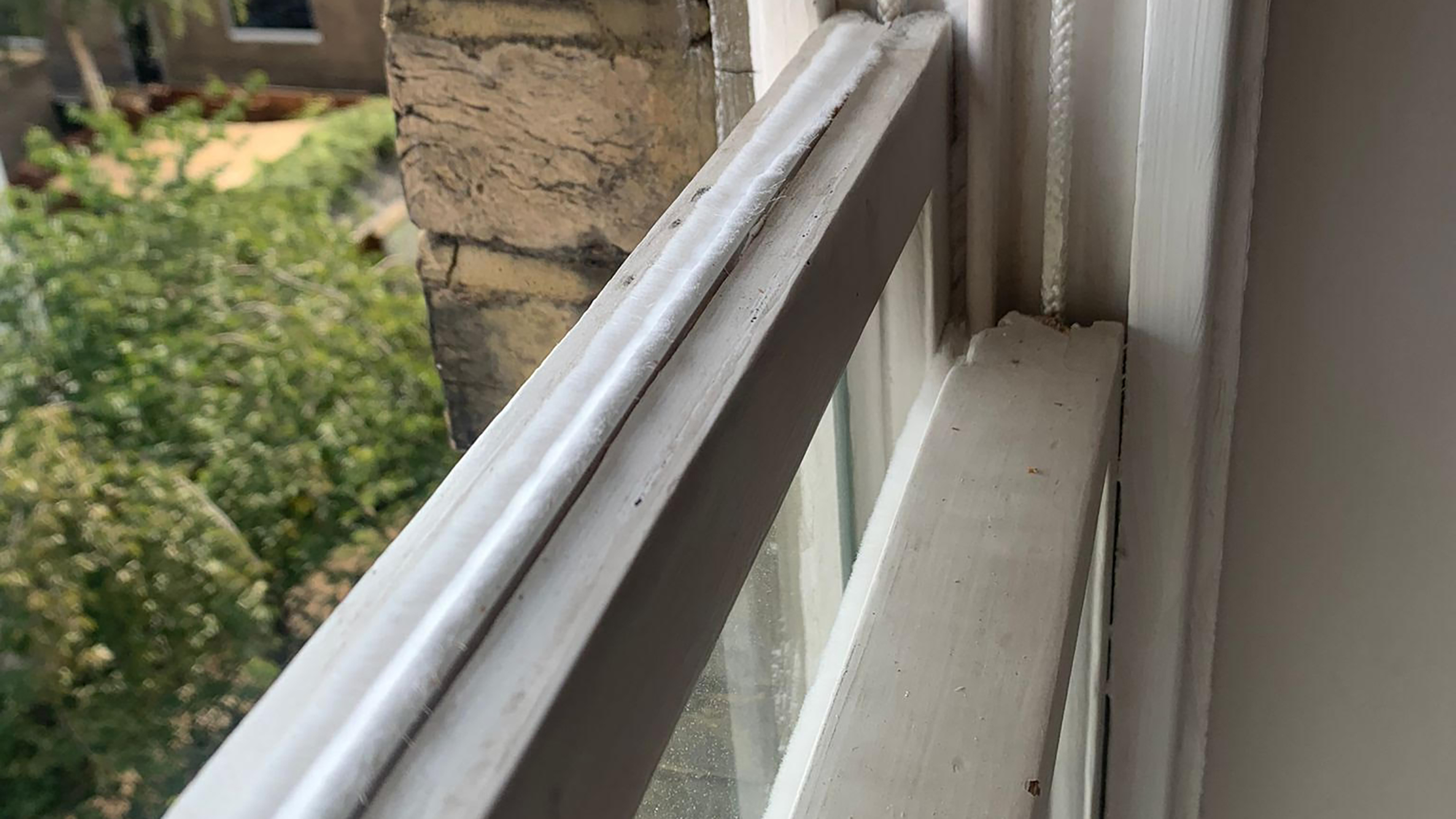

Original sash windows immediately add a sense of character and charm to period homes so everything that can be done, should be done, in order to repair and retain them rather than replace. Draught proofing is one of the most common upgrades required for this style of window.

Given that sash windows were a common feature on houses during the Georgian and Victorian periods, many that remain in place will be well over a hundred years old — so it is no wonder that they often rattle around in their frames and have gaps through which cold winds can blow.

In order to draught proof sash windows, a slightly different approach to that used on other types of windows often needs to be taken. Here, we take a look at the best methods to use, as well as exploring the ways in which the professionals approach the job.

Can you draught proof sash windows on a DIY basis?

There are several ways you can draught proof sash windows yourself. It is a job that does require a little more consideration than when insulating windows of other styles, such as casement. This is because the sliding motion of the windows can cause adhesive draught strips to come loose relatively quickly.

There are many different products on the market designed to draught proof windows but not all are effective.

The main ways to draught proof sash windows on a DIY basis are:

- Silicone sealant

- Self-adhesive weatherstrips

- Self-adhesive brush seal weatherstrips

- Metal weatherstrips

- Temporary window sealer

Should I use silicone to draught proof my windows?

Seen by some as a rather drastic approach to draught proofing, this is a solution that will not suit everyone's needs.

"If you're quite happy having your window fixed shut because it’s rarely, or possibly never, used then it would be advisable to seal the window closed with a silicone," says Brian Turner at London Sash Window Repairs Ltd.

"This completely eradicates the draughts and will have a big impact on the temperature of your room when you crank up the heating. The transformation will be quite shocking and by far produces the best results of all DIY sash window draught proofing — and instantly too."

Silicone sealant is readily available and easy to apply, but once it is in place, it is not so easy to remove. Bear in mind that if the window is needed as a fire escape this is not a viable option, plus there is another important consideration to bear in mind.

"The other problem might come in the form of not being able to claim an energy efficiency upgrade on your EPC certificate," says Brian Turner. "Despite the fact sealing a window shut is more efficient than a draught proofing system, and is going to offer the same reduced carbon footprint, it might not be recognised as such."

Do adhesive draught strips work on sash windows?

A really popular method of draught proofing sash windows is to use self-adhesive weatherstrips. These are usually sold in rolls and are designed to be cut to size and stuck into place.

Although cheap and quick to fit, there are not necessarily the best option for sash windows. In fact, the Energy Saving Trust advises against them in this instance, suggesting silicone sealant as a better option.

"Stick on draught proofing isn’t always that effective long term because as you use your windows, the movement will dislodge the draft seals, but it certainly is cheap and very easy to install, says Brian Turner.

"Almost anyone will be able to successfully draught proof their sash window using this DIY sash window draught proofing method. On top of that, if the install is neat and tidy, it shouldn’t effect the function of the sash window all that much."

Are brush seals a good way to draught proof sash windows?

Another option for anyone after a DIY method to draught proof sash windows is to use metal or plastic strips with brushes or pile strips attached — known as brush seals or strips.

These come in many different guises. They are commonly sold in two parts, with a self-adhesive 'pile carrier' – rebated plastic or metal strips – designed to be stuck around the window frame into which the fluffy brush or pile strips are slotted to stop draughts.

While these do prevent draughts, do bear in mind that they many need replacing in time depending on how often you open and close your windows.

Metal and plastic strips with wipers or 'V-strips' are usually better suited to casement windows rather than sash windows.

Are there any temporary ways to prevent draughts?

There are several products on the market now that are designed to seal up sash windows during the colder months before being removed again when the weather warms up and you want to open the window.

One such product is Gapseal. It comes ready to fit into window gaps between 2mm-7mm and with all the tools needed to secure it into place. Once fitted, it expands to fill the entire gap yet can be taken out when no longer required.

What methods do professionals use to draught proof sash windows?

For many people looking at repairing sash windows, the best option when it comes to draught proofing is to call in the professionals. Not only will they be able to offer advice on the best method for your particular windows, but they should also be able to repair damaged sections in order to improve their efficiency even further.

"Professional systems use draught seals that are machined and rebated into the original sashes," says Brian Turner. "Parting beads and staff beads are then replaced with a like-for-like mould that has a draught seal hidden and pre-installed.

"Brush pile is inserted into all perimeters of your sash window to achieve a complete seal. The top of the top sash, meeting rails, lower rail of lower sash, parting bead, and staff bead all have draught seals installed," he continues.

"We use a pile carrier that is glued in situ, and then once set firmly, a brush pile is inserted into the channel. Using this two tier system, as opposed to directly installing into the sash creates the additional benefit that if a draught seal is damaged or painted and is no longer effective, replacement of the draught seal is a two minute job and can be done by the homeowner, costing just a few pence."

How much does draught proofing cost?

The method you choose will dictate what you pay to draught proof sash windows.

Self-adhesive weatherstrips cost around £5-£6 for a 5m roll, while self-adhesive brush pile carriers measuring 2.2m cost as little as £1.40.

According to the Energy Saving Trust: "Professional draught proofing could cost around £225 for your whole house (based on a typical semi-detached property in England, Scotland or Wales.)"

Get the Homebuilding & Renovating Newsletter

Bring your dream home to life with expert advice, how to guides and design inspiration. Sign up for our newsletter and get two free tickets to a Homebuilding & Renovating Show near you.

Natasha was Homebuilding & Renovating’s Associate Content Editor and was a member of the Homebuilding team for over two decades. In her role on Homebuilding & Renovating she imparted her knowledge on a wide range of renovation topics, from window condensation to renovating bathrooms, to removing walls and adding an extension. She continues to write for Homebuilding on these topics, and more. An experienced journalist and renovation expert, she also writes for a number of other homes titles, including Homes & Gardens and Ideal Homes. Over the years Natasha has renovated and carried out a side extension to a Victorian terrace. She is currently living in the rural Edwardian cottage she renovated and extended on a largely DIY basis, living on site for the duration of the project.