Air source heat pump costs — how much should you budget for one?

If you're looking at air source heat pump costs for your self build or renovation, here's everything you need to know about calculating how much to set aside

Bring your dream home to life with expert advice, how to guides and design inspiration. Sign up for our newsletter and get two free tickets to a Homebuilding & Renovating Show near you.

You are now subscribed

Your newsletter sign-up was successful

While air source heat pump costs may still be eligible for grant assistance, what can you expect to pay on average if you choose one for your self build or renovation?

Does the cost vary if you're installing an air source heat pumps to replace an existing heating system, or are the costs similar regardless of whether you're modifying or starting from scratch?

And once it's installed, what can you expect to pay for running one? As well as accurate design and good installation being crucial to ensuring an air source heat pump runs efficiently, we take a look at all the other factors that can influence the cost of installing and running one in your home.

How much are air source heat pump costs to buy and install?

In much the same way as the cost of any heating system can vary considerably, air source heat pump costs are no different. However, there is an average figure that can be assumed for most properties.

"The typical cost to buy and install an air source heat pump (ASHP) is generally between £12,000 and £15,000," says Olivia Downing, head of marketing at NIBE.

"In England and Wales, households can claim the Boiler Upgrade Scheme (BUS) grant which is £7,500, which helps towards the cost. Costs can vary depending on the system type and the specific requirements of the property.

Daikin’s residential product manager, Hamid Salimi, agrees telling us: "The average cost of installing an air source heat pump in an existing property is around £13,000. However, government grants in England, Wales and Scotland can reduce this by £7,500 to £5,500, but they are slightly different depending on your location.

Bring your dream home to life with expert advice, how to guides and design inspiration. Sign up for our newsletter and get two free tickets to a Homebuilding & Renovating Show near you.

"In England and Wales a grant of up to £7,500 is available via the BUS. The Home Energy Scotland Grant and Loan Scheme provides a grant of up to £7,500, an interest free loan or a combination of both to install. For air source heat pumps, the interest free loan is up to £7,500 with a further £1,500 for rural and island properties."

But, the reality is that in some instances these prices can rise if you're installing an air source heat pump in an existing property, rather than a new build. So what can affect the costs and are there ways of potentially protecting yourself against the increase?

Olivia Downing, NIBE’s Head of Marketing, has a remit at NIBE is to help take the brand to the next level, as well as helping people understand how the technology works as well as pointing out the significant benefits it can bring. NIBE offers an unbeatable combination of exceptionally powerful sustainability credentials and a strong heritage with deep roots in Sweden – the best-use case you could possibly get for heat pumps.

Hamid Salimi is National Residential Product Manager at Daikin UK. Hamid has worked with Daikin for over 13 years and now covers all aspects of residential renewable heating.

Factors influencing air source heat pump costs

If you've ever asked the question are heat pumps suitable for old homes, you'll know that in most cases the answer is yes. But, choosing to upgrade your home's heating system from a traditional one such as gas or LPG, can see your air source heat pump costs rise to around £30,000 in the most complex of cases.

The cost is largely influenced by the details of the installation," advises Olivia Downing. "For example, if the property needs new pipework, if a hot water cylinder needs to be added or upgraded, or if radiators need replacing to suit the lower flow temperatures of heat pumps, this will impact the overall cost. The age, size, and insulation levels of the home also play a role.

"In addition, In contrast, new builds can be designed with low-temperature heating in mind from the outset, which often makes installation more straightforward and cost-effective," she adds.

Hamid Salimi expands further:

- Insulation – A well-insulated property will reduce the heat loss of the property and will make a heat pump more economical to run, so it is advisable to take a fabric first approach and improve the insulation levels before a heat pump is installed.

- Size – As a general rule of thumb, less insulated properties also require bigger more expensive units, so the more you can upgrade your home the more chance you have of avoiding increased costs

- Complexity – If the installation is more complex, it will require more materials such as pipework and other hydraulic components and take longer to install, therefore increasing labour costs. You may need a new water tank and to change your system from 'open vented' to 'unvented'. And if you're replacing electric storage heaters then a complete wet central heating system will need to be installed, also adding a lot of disruption and cost

- Radiators – Because heat pumps typically operate at lower temperatures than fossil fuel boilers, some or all of the radiators may need to be replaced with larger capacity units. Installing high temperature heat pumps, that operate at higher temperatures, can remove, or reduce the number of radiators that need to be replaced

- Regulations – Most heat pumps don’t require planning permission, but if you live in a listed building or a conservation area, or if the heat pump size exceeds a certain limit you will need to get the necessary planning permissions and consents and these will come with a fee attached to them

- Removal – There may also be a cost in removing the existing boiler. In the case of oil or LPG, the removal of fuel storage tanks, concrete base and fuel pipework will also need to be factored in

Other factors that impact air source heat pump costs

Outside of the installation costs, other impacting factors relate to the type of ASHP you need to heat your home. Size, brand and quality will all play a part.

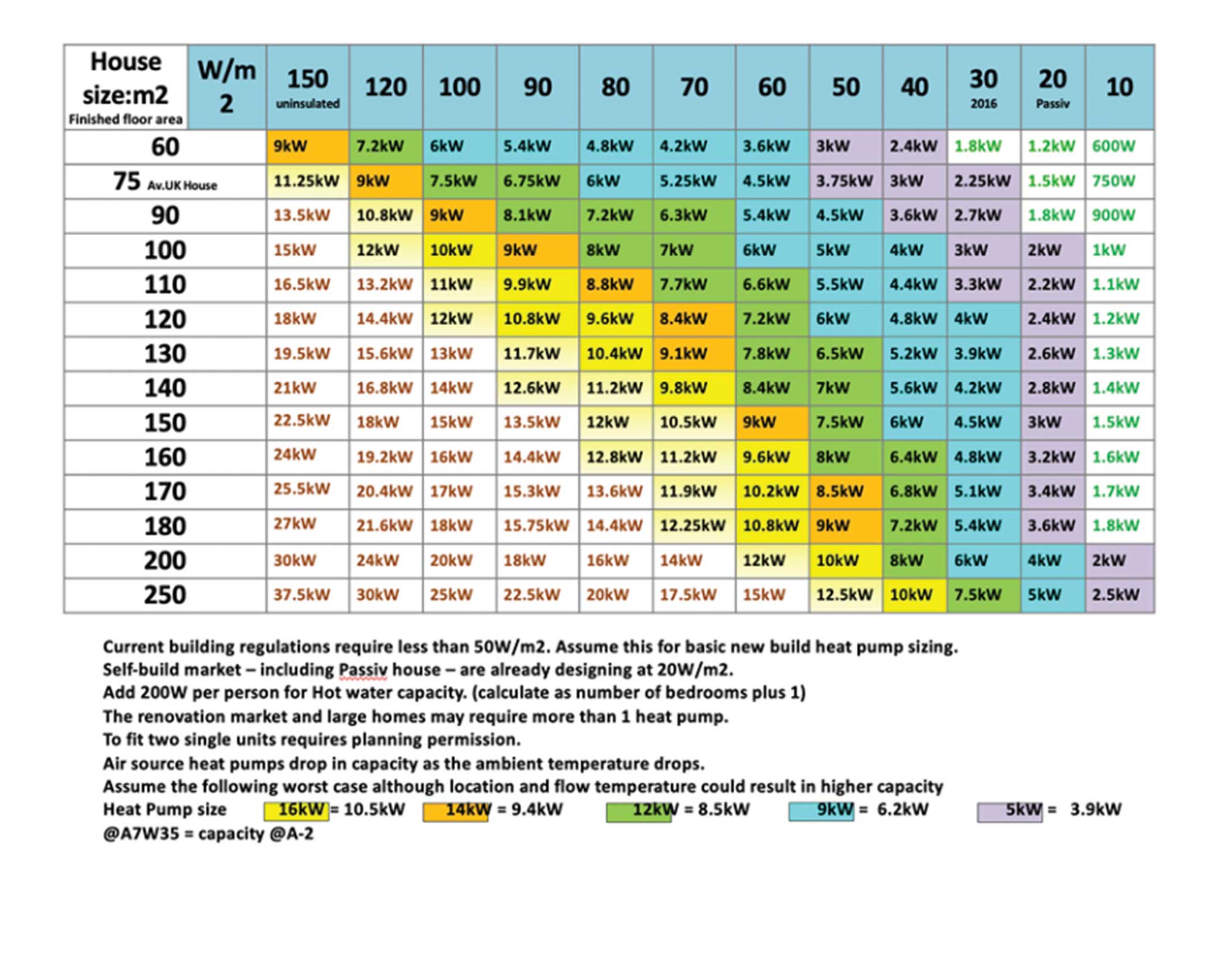

Smaller heat pumps will be suitable for smaller properties and well-insulated low-energy homes. A low-energy eco house may need around 10 Watts per square meter of finished floor area (1kWh for a 100m2 home) up to around 70 watts per square meter (7kWh for a 100m2 home), for instance.

However, as the heat load increases so does the need for larger capacity units and bigger volume cylinders. These will, in turn, add to the upfront costs.

What's more, larger properties may also need a bigger heat pump, or you may have to question if you need one heat pump or two, which can in turn require a hydraulic design which is more complex. What's more, a higher heat requirement could also mean higher flow temperatures and therefore higher running costs.

The below table illustrates how the size of the property and the insulation levels impact the size of air source heat pump required:

Air source heat pump costs compared to other heating types

Weighing up air source heat pump costs compared to other types of heating, such as heat pumps vs gas boilers involves looking at four things: cost, installation, efficiency and running costs. While we've covered the practicalities of the first two points, it is worth noting that it's in the efficiency stakes where ASHPs can have a greater advantage.

"In terms of efficiency, air source heat pumps are significantly more efficient than gas boilers," notes Olivia Downing. "A typical gas boiler is around 90–97% efficient, whereas a heat pump can be up to 400% efficient – meaning you could get up to four times as much heat for every unit of electricity used.

"Ground source heat pumps (GSHPs) can be even more efficient than air source models," she adds, "but are typically more expensive to install due to the need for underground pipework."

"Replacing a gas boiler with another gas boiler can cost between £1,200 and £4,500, depending on the system that is being replaced and the one that is being installed, while oil boilers can cost between £2,000 and £8,000," says Hamid Salimi.

So while a gas boiler is cheaper to buy and install, the carbon savings are potentially much higher with an air source heat pump and the long-term running costs should also be better, especially if combined with solar panels and/or selective electric tariffs that optimise off-peak cheaper rates.

An air source heat pump is also typically less expensive to install as compared to other renewable heating systems such as biomass boilers, which means weighing up whether you should swap a boiler for a heat pump, is a decision that needs careful consideration.

Running costs for an air source heat pump

Calculating your home's energy costs using an air source heat pump will come down to how big your home is and how energy efficient it is. However, at the moment, there's no doubt heating bills quickly add up.

Let's say your home requires 12,000kWh per year and the efficiency of the heat pump is 300% then you will require 4,000 units of electricity to power the heat pump. At the current rate of 27.03p per kWh (electricity) that is a running cost of £1,081.20 per year.

However, if the efficiency of the heat pump is 400% then you will use 3,000 units of electricity at a cost of £810.90 per year.

"The annual bills for air source heat pump costs depend heavily on your electricity tariff and how the system is used," says Olivia Downing. "Some energy providers offer heat pump-specific tariffs, which can help optimise running costs, so while it's difficult to give a universal figure, heat pumps are generally more efficient than other electric heating systems and can offer savings over time compared to fossil fuel alternatives, especially in well-insulated homes."

"Based on the current energy price caps a four-bedroom property with a typical heating demand of 17000kWh, could save you over £205 a year in running costs with a Daikin air source heat pump compared with a gas boiler, over £166 a year in running costs compared with an oil boiler, or over £227 a year compared with an LPG boiler," claims Hamid Salimi.

"By switching to a dedicated heat pump tariff, these savings could increase," he adds. "For example, the savings could triple, saving around £690 a year in running costs compared with a gas boiler.

"But the financial savings are only part of the picture," says Hamid. "We need to reduce harmful carbon emissions if we are going to limit the damage to our planet and address climate change. A heat pump can reduce these emissions by up to 70% compared with a gas boiler. Also, a well-maintained heat pump outlasts the gas/oil boiler."

FAQs

How can I calculate my ASHP running costs?

So, how do you establish how much energy your home will require, to in turn establish the running cost of an ASHP in your home?

To begin, heat pump installers that are installing in accordance with Microgeneration Certification Scheme (MCS) standards will evaluate the insulation and airtightness levels in the home and produce a room by room heat loss calculation. (MIS 3005 is the MCS installer standard for heat pumps and includes said heat loss calculation tool within it.)

This calculation should be able to determine the maximum heat load at the design outdoor temperature as well as the amount of energy required to heat the home seasonally.

If the insulation is optimised and the emitters (radiators or underfloor heating) are also designed for low temperatures, then the flow temperature of the heat pump can be lower and therefore the efficiency will be higher. As such, the heat pump will cost you less to run.

Typically you can expect efficiencies of between 200% (at high flow temperatures of around 55°C) to around 400% (at low temperatures of around 35°C).

Hot water requires higher temperatures than space heating and as such the efficiency of a heat pump will be lower for hot water preparation than space heating. Once you have the figure for space heating an allowance must also be made for heating hot water. Allow around 50 litres of hot water per person per day.

To work out how much energy your home will use you can use a free spreadsheet calculator on MIS 3005 if you have some experience of spreadsheets. When you know the heat loss you will then be able to factor in the efficiency of the heat pump.

The installer has traditionally done the design work as well as the installation work, but MCS has now changed to allow for specialist designers and specialist installers to undertake this.

What is the payback period for an ASHP?

Homeowners looking for a clear cut answer to whether there is a defined payback period for investing in an ASHP will find that there isn't a direct response as it will need to be evaluated against a number of criteria.

"The payback period depends on the cost of installing and running the system," says Hamid Salimi. "In a new build property, for example, the labour costs are much cheaper. "

Olivia Downing agrees, confirming, "there’s no single payback period, as this will vary depending on the property, system design, insulation levels, the cost of installation, and energy tariffs. However, many homeowners see a return through lower running costs, reduced carbon emissions, and potential increases in property value – especially as demand for low-carbon homes grows."

"Perhaps the biggest variable is the price of running the system," adds Hamid Salimi. "In the UK, for example, the Energy Price Cap can change on a quarterly basis. Moreover, the cost of electricity is around four times as much as the price of gas. The government are looking at reducing this and, when this comes down, it will reduce the payback period.

"Energy suppliers have also started offering lower tariffs and variable tariffs, and if these can be used, the running cost will eventually be much lower."

How can I make sure my ASHP costs don't escalate?

Investing in air source heat pump costs can mean an initial outlay of money and so it's not uncommon for homeowners to look for ways of saving money. However, with the technology still relatively new, and still being improved, one of the ways you can ensure your costs don't increase in the future is by investing in a qualified installer in the first place. Don't be tempted to cut corners at what is the most crucial stage.

"Having a heat pump system designed and installed correctly is essential to making sure your house is warm and your bills aren’t too high. Every home is different, and factors like its size and energy efficiency effect the output and set-up of the heat pump, which is why it’s really important to choose a heat pump installer who knows what they’re doing," confirms Mark Krull from Logic4training.

It will also save you money in the beginning he adds, "as to be eligible for the BUS you must choose an engineer that can sign off the install under MCS. MCS accredited businesses have met strict quality standards and the scheme provides consumer protection.

"Some installers provide the MCS part using an external company, but what’s key is that your heat pump system is designed, installed and commissioned in accordance with MCS so it works properly and meets the funding criteria."

The added bonus is that a registered installed can also take care of accessing the grant on your behalf and simply present you with a bill showing the reduced amount at the end.

"In addition," adds Mark, "check to see if they have membership with trade bodies like TrustMark, the Renewable Energy Consumer Code (RECC), Chartered Institute of Plumbing; Heating Engineers (CIPHE) or the Heat Pump Association (HPA) as these schemes offer additional consumer protection.

"Look for reviews on Google. Do they have a Facebook page, are they a member of Trustpilot or Checkatrade? Ask them about any local jobs they’ve completed recently and ask to speak to a happy heat pump customer," advises Mark. "Word of mouth is still one of the best ways to find a reputable trades person, so ask your friends and family."

Being affiliated with a particular heat pump manufacturer is not a must, but it's important to know that some of the major brands offer extra-long warranties and back-up should things go wrong.

"Installers affiliated with manufacturers may have had additional training too, but whether to a particular manufacturer or not, it’s worth asking what their aftercare protocol is," says Mark. "You don’t want to be left with a cold house and extra bills should something go wrong."

Mark Krull is Director of LCL Awards, the leading certification body for renewable qualifications in the UK, and the South East’s premiere building services training provider, Logic4training.

As well as choosing the right installer, make sure that you know the best place for air source heat pump positioning and understand how choosing a low vs medium vs high temperature heat pump could also impact on your air source heat pump costs.

David is a renewables and ventilation installer, with over 35 years experience, and is a long-standing contributor to Homebuilding and Renovating magazine. He is a member of the Gas Safe Register, has a Masters degree in Sustainable Architecture, and is an authority in sustainable building and energy efficiency, with extensive knowledge in building fabrics, heat recovery ventilation, renewables, and also conventional heating systems. He is also a speaker at the Homebuilding & Renovating Show.

Passionate about healthy, efficient homes, he is director of Heat and Energy Ltd. He works with architects, builders, self builders and renovators, and designs and project manages the installation of ventilation and heating systems to achieve the most energy efficient and cost effective outcome for every home.